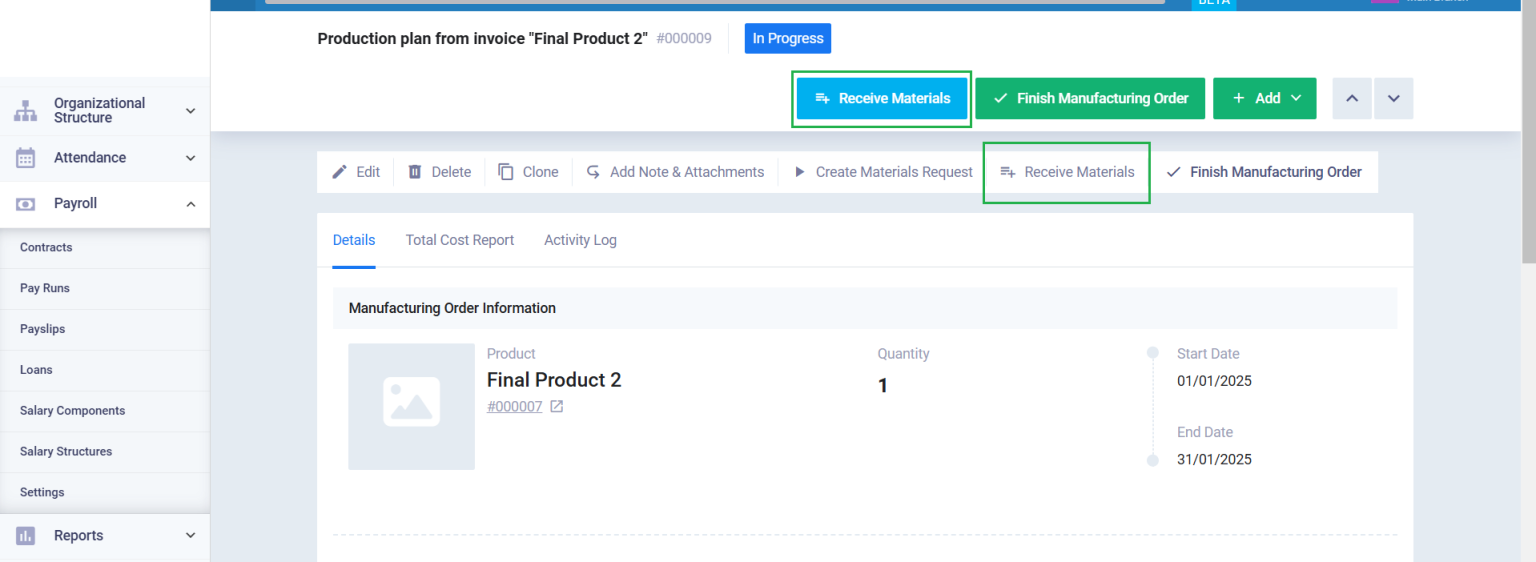

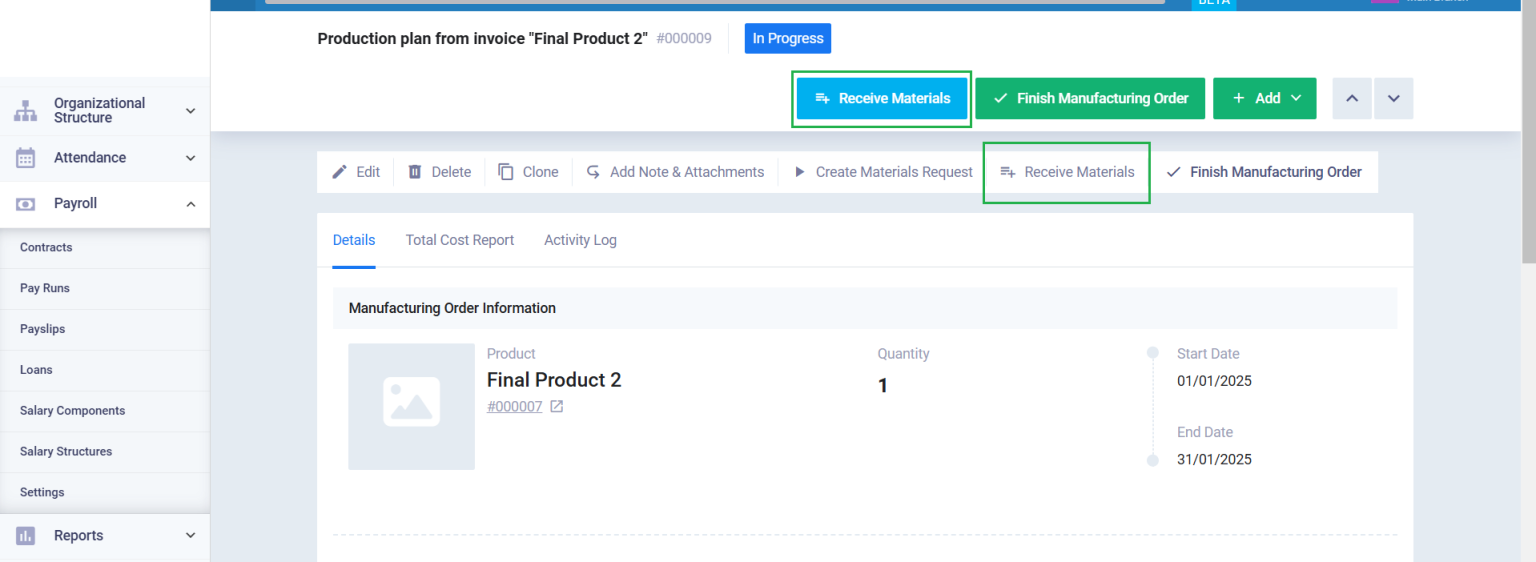

Click on “Manufacturing Orders” under the “Manufacturing” dropdown in the main menu. Then, select the desired manufacturing order for which you want to receive raw materials and click on “Receive Materials.”

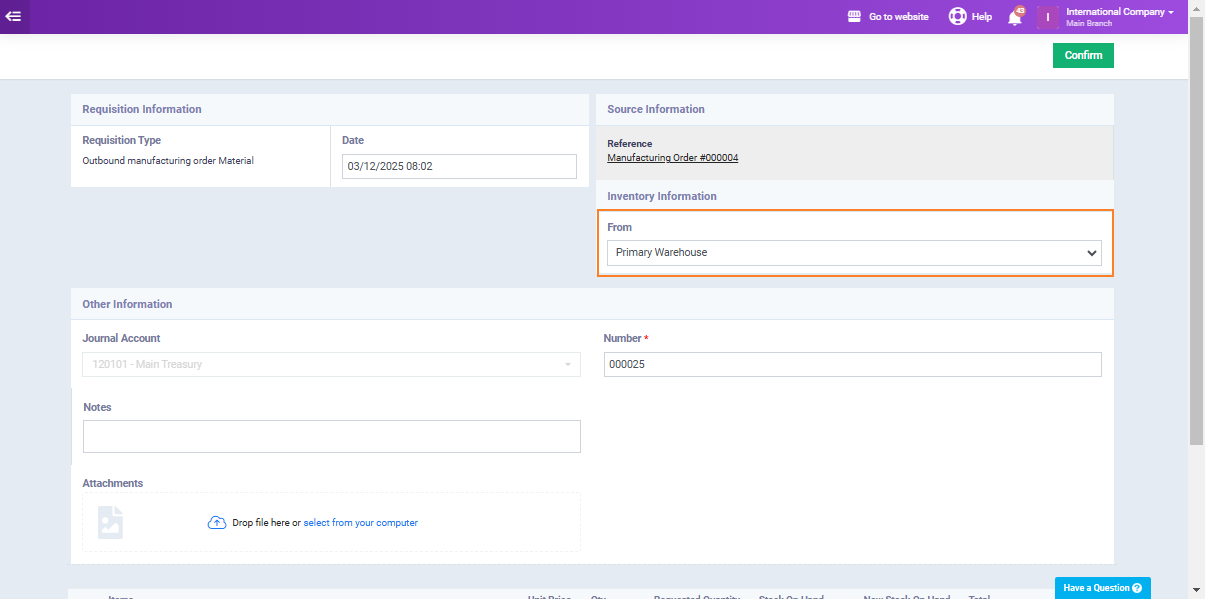

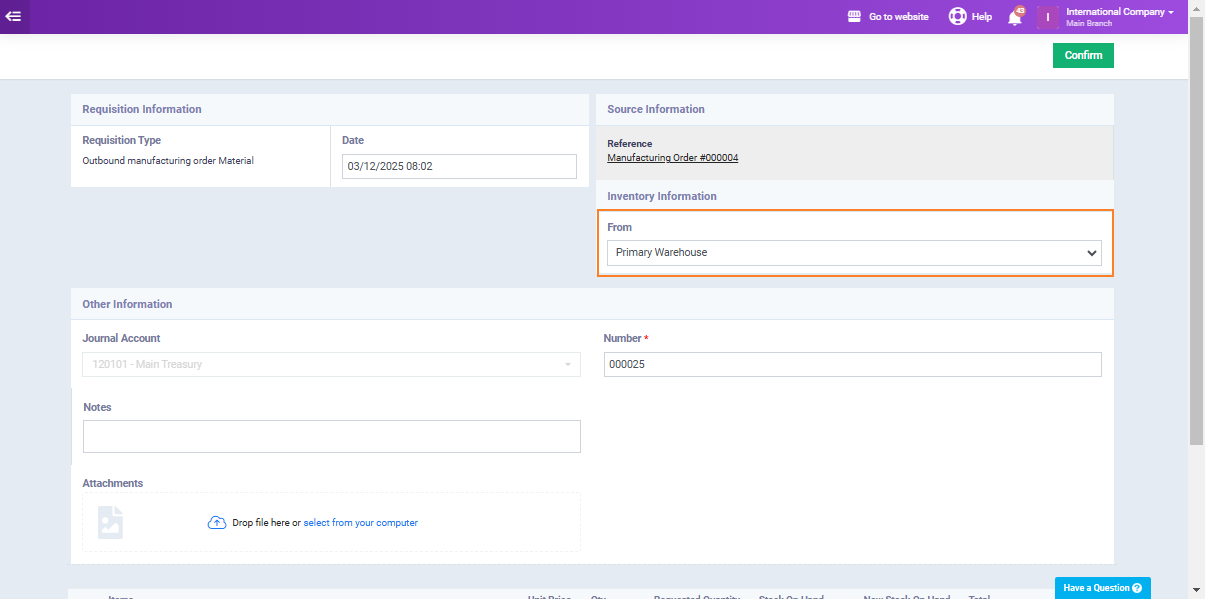

Enter the requisition details:

- Date: This is automatically set to the current date when the requisition is created, but you can change it if needed.

- Warehouse: Choose the warehouse from which the stock items listed in the order will be issued.

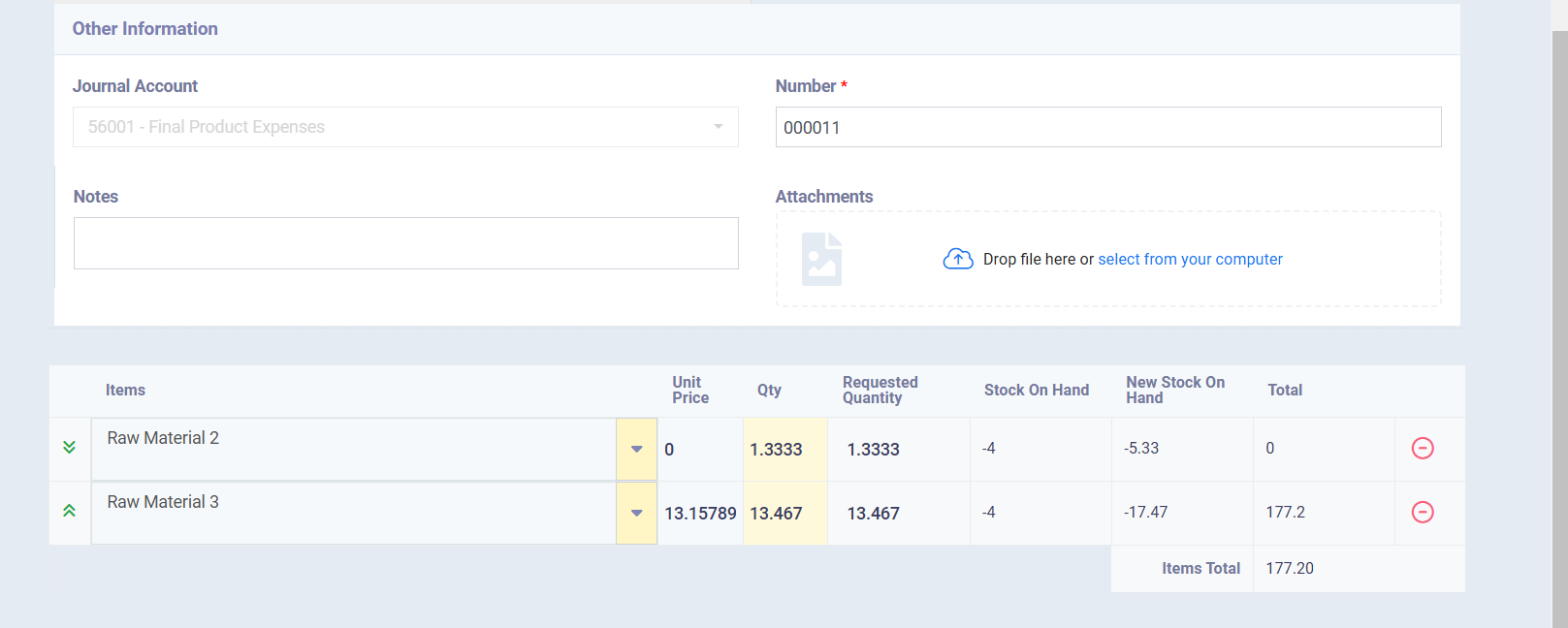

- Journal Account: The account specified in the manufacturing order is automatically assigned.

Notes and Attachments: If there are any notes or files related to the material requisition, you can add them here.

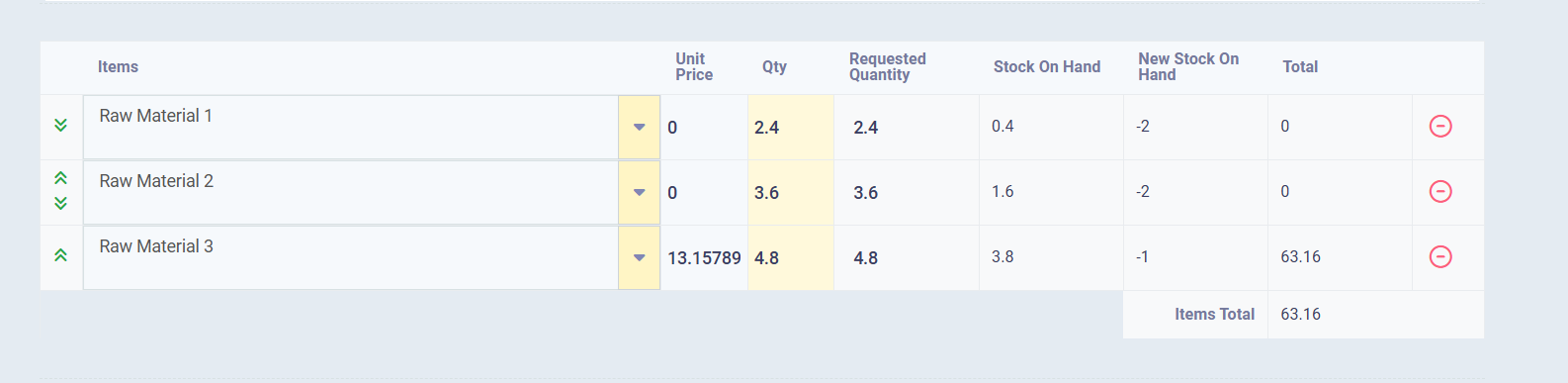

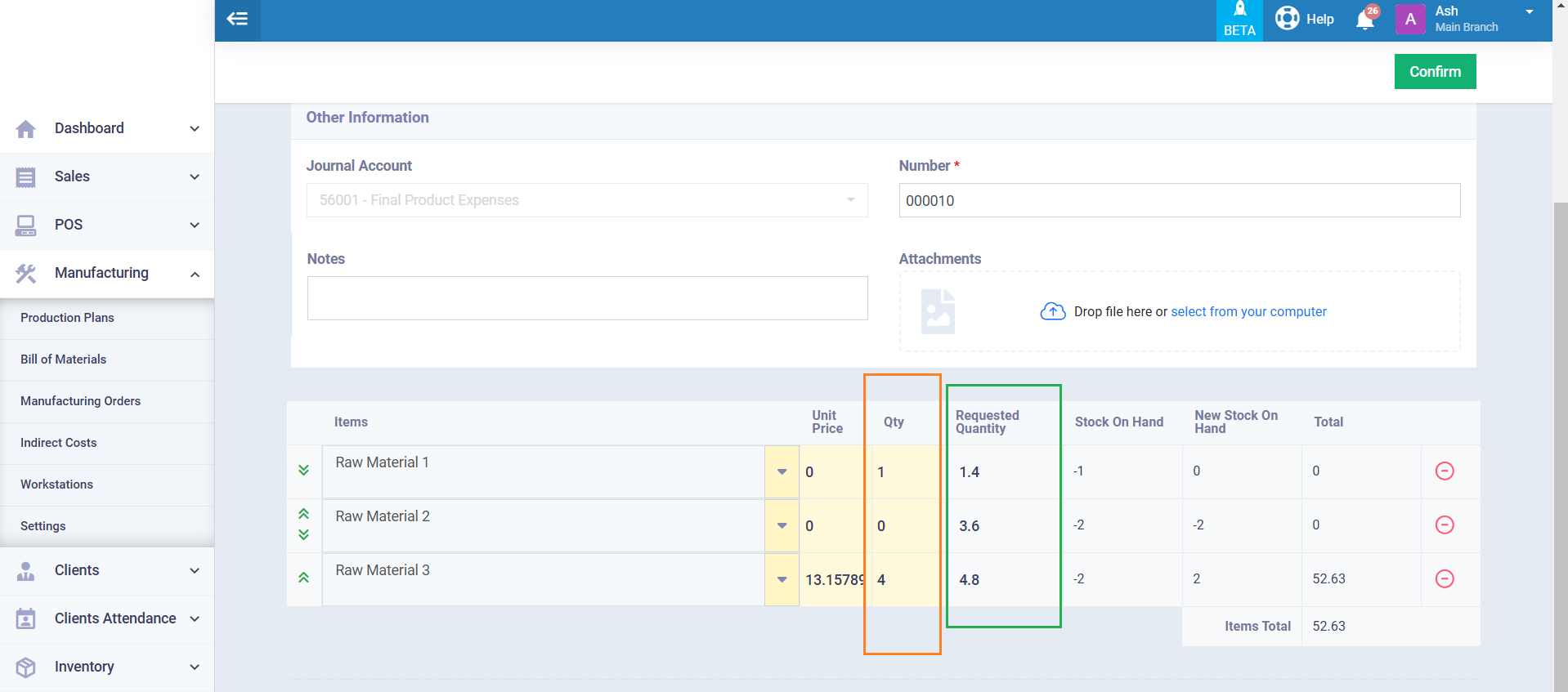

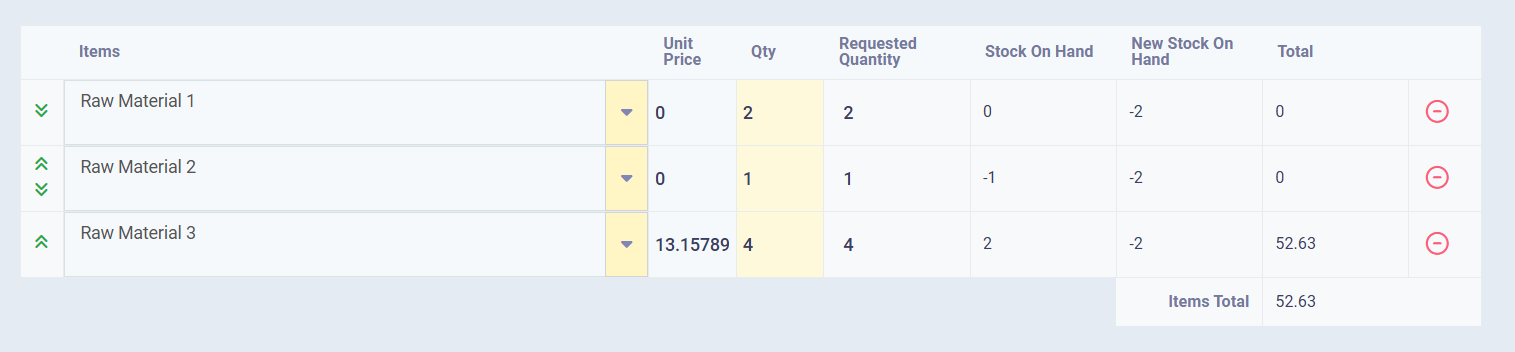

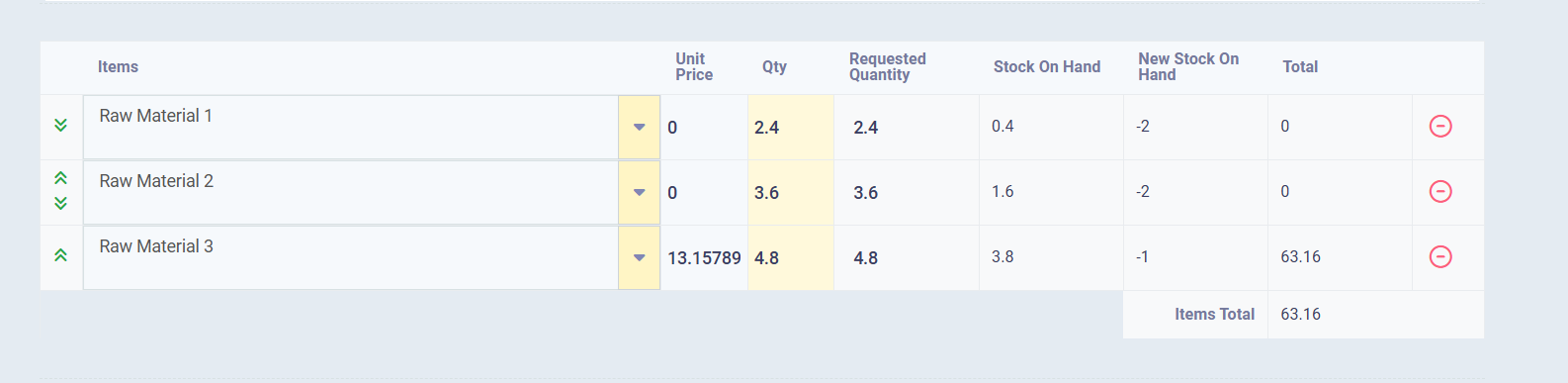

Items: The raw materials specified in the manufacturing order, along with their respective quantities, are automatically displayed. You will also see the stock balance before and after confirmation of the raw material requisition.

- If you want to modify the quantity of raw materials in the requisition to exceed the quantity specified in the manufacturing order, you need to enable this setting from the Manufacturing Order General Settings.

- If you want to partially receive the raw materials, you can delete some items when creating the requisition or reduce the specified quantities. You can receive the remaining quantities at a later time.

- To add new raw materials, click the “+Add” button.

Finally, click on the “Confirm” button to finalize the process.

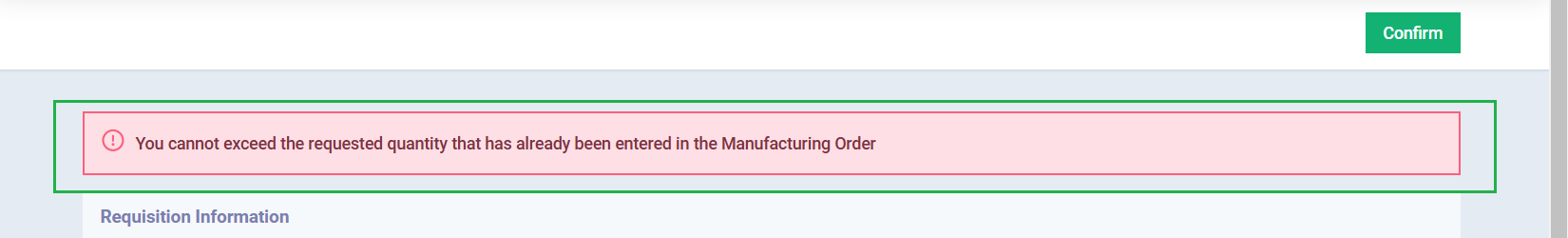

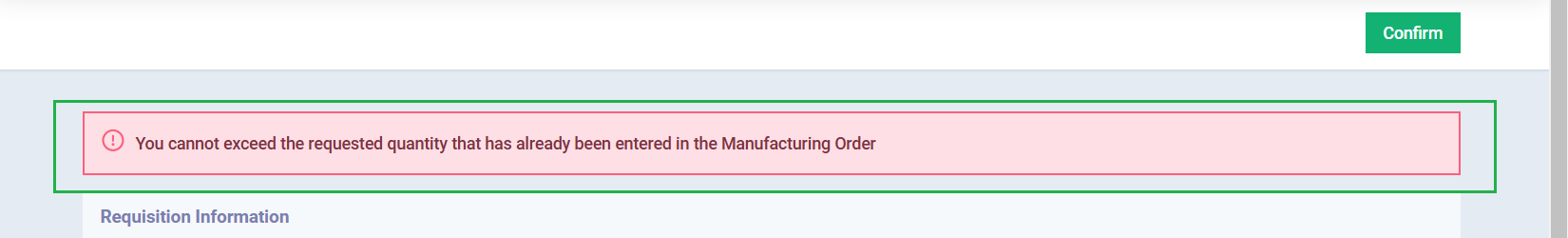

If the quantity of raw materials in the stock requisition exceeds the specified amount in the manufacturing order without enabling the “Exceeding The Requested Quantity In The Manufacturing Order” setting, the following error message will appear:

“You cannot exceed the requested quantity that has already been entered in the manufacturing order.”

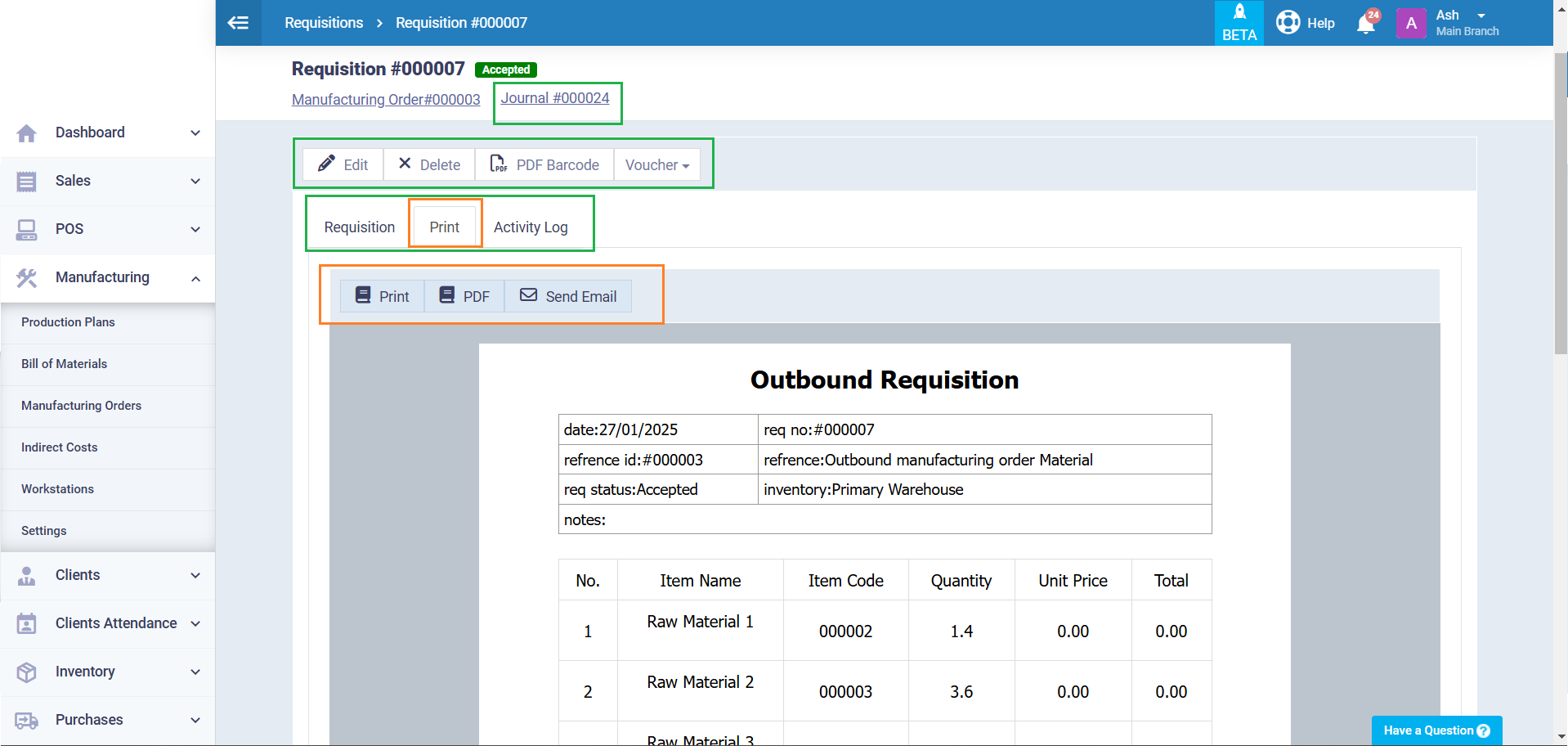

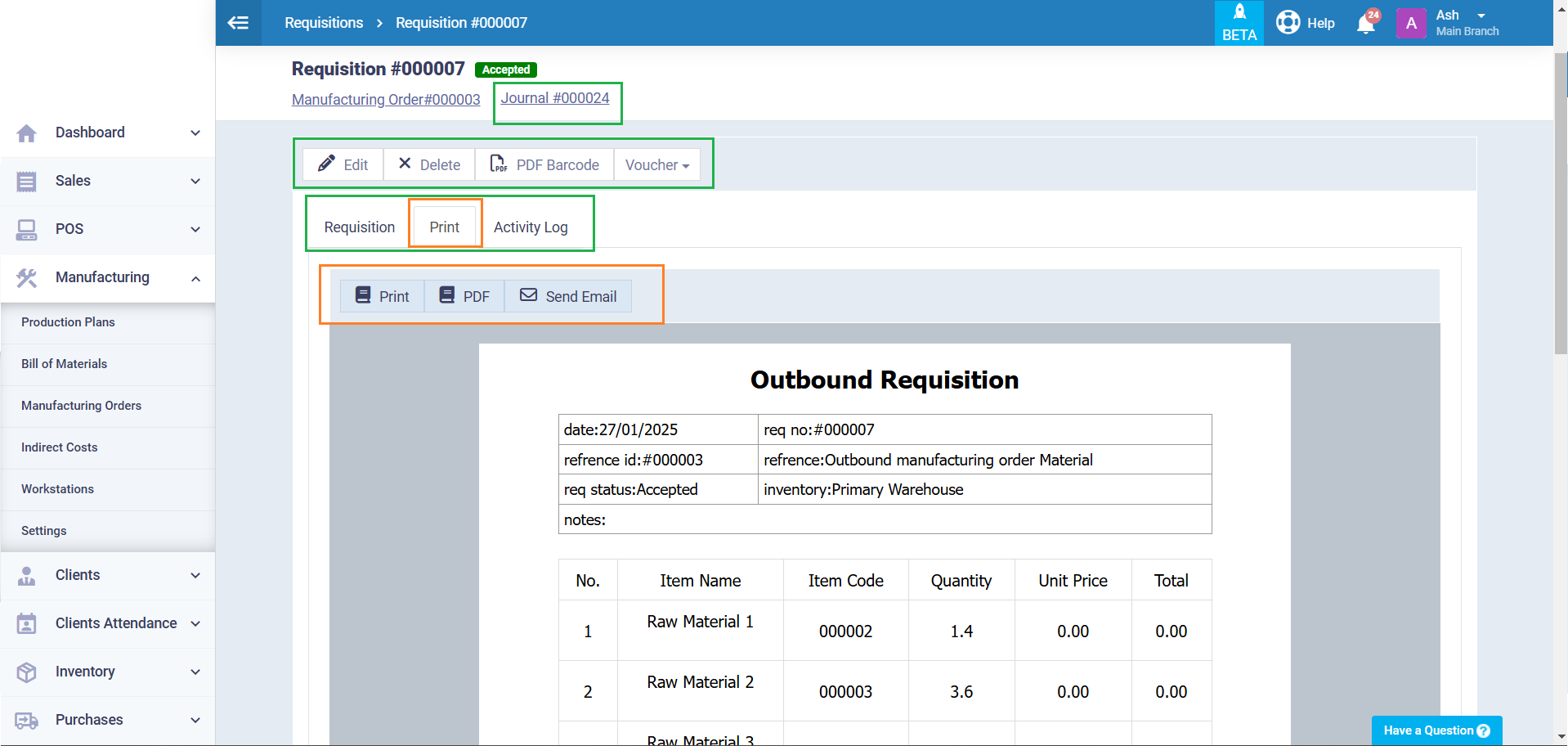

You can perform several actions on the raw material requisition, such as “Edit,” “Delete,” using one of the “Print Vouchers,” or Download and Print “PDF Barcode.”

Additionally, you can easily view the “Details” and “Activity Log” related to the Raw Material Receipt, as well as “Print” the outbound requisition or send it via email.

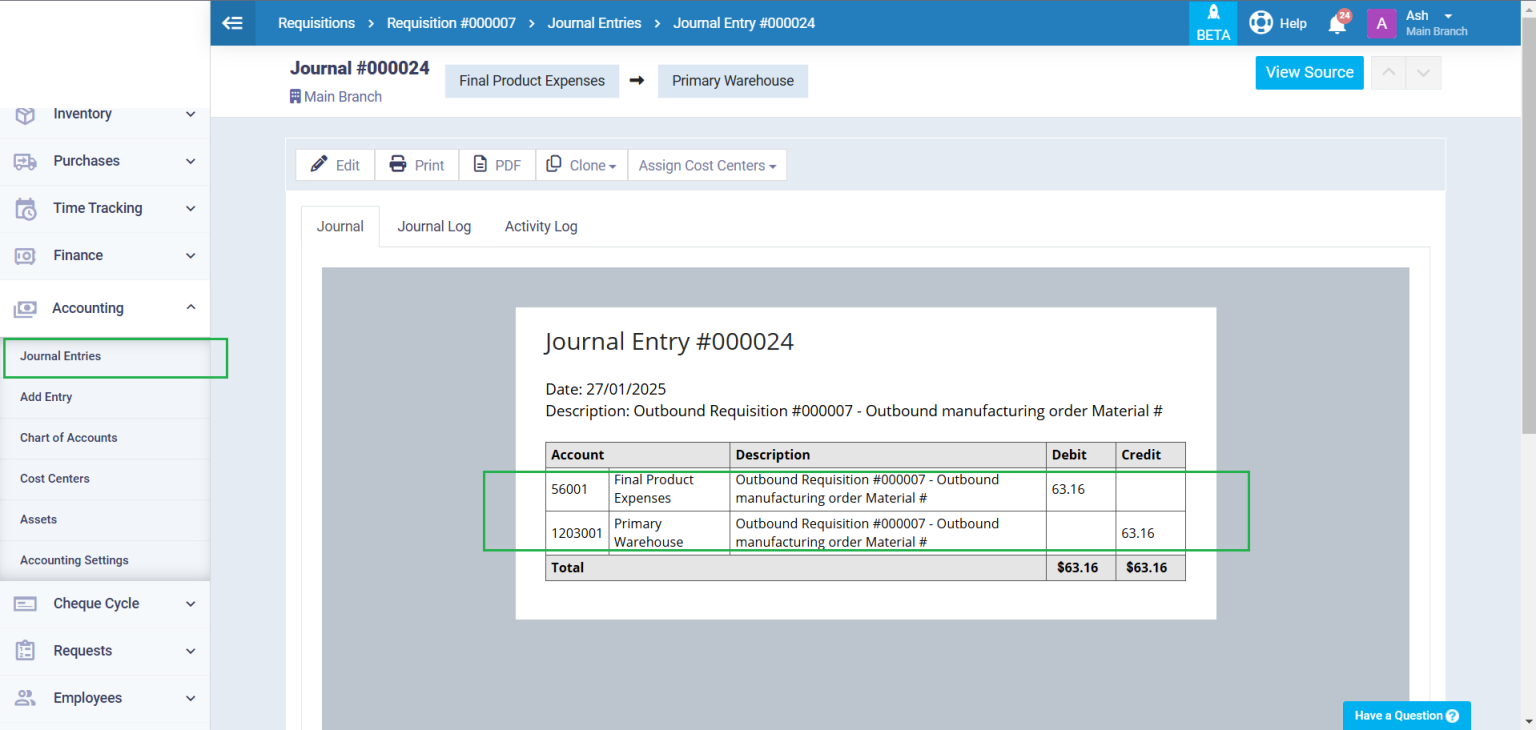

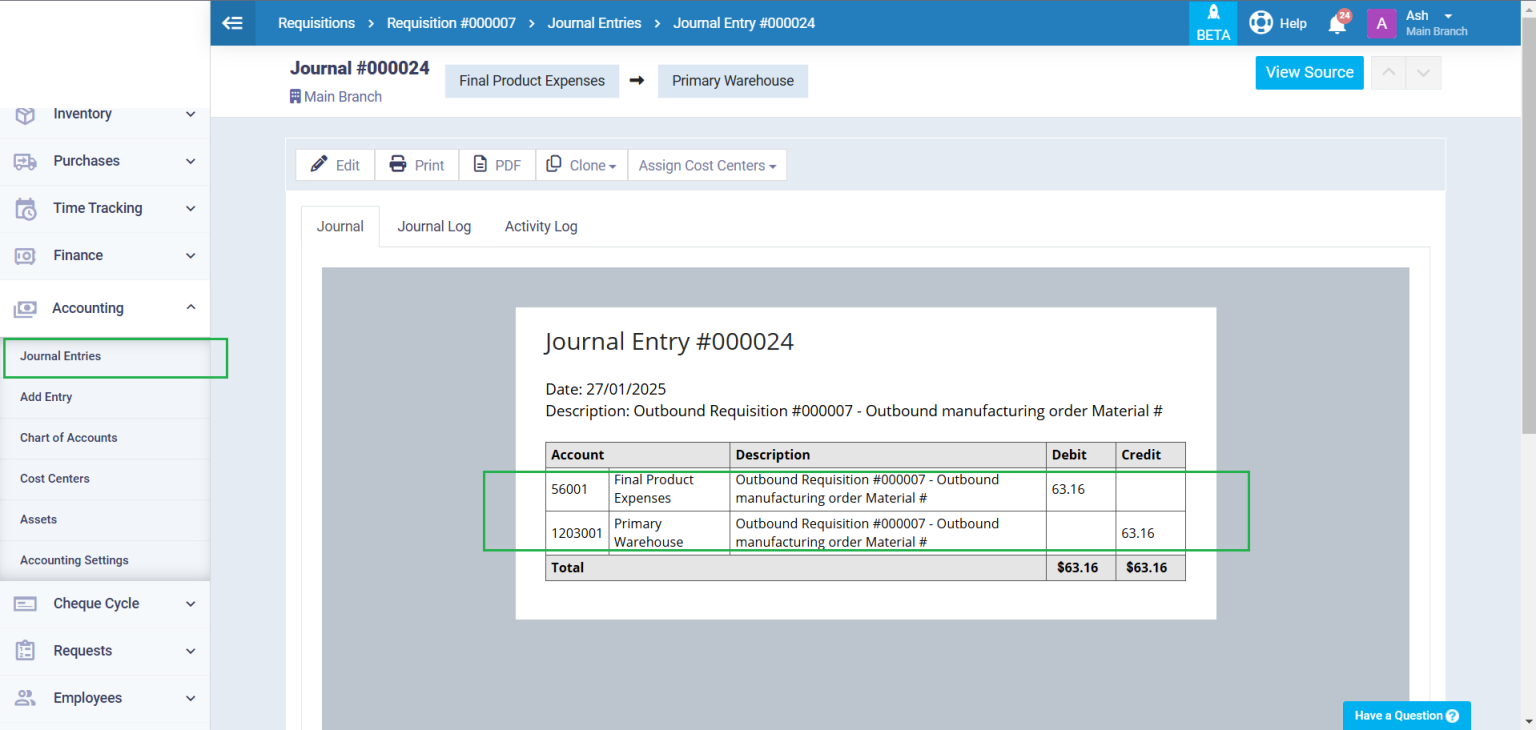

After confirming the stock requisition, the journal entries for received material are automatically created. You can access these entries by clicking on “Journal Entries” under the “Accounting” dropdown in the main menu or by clicking on the journal entry number displayed on the stock requisition screen.

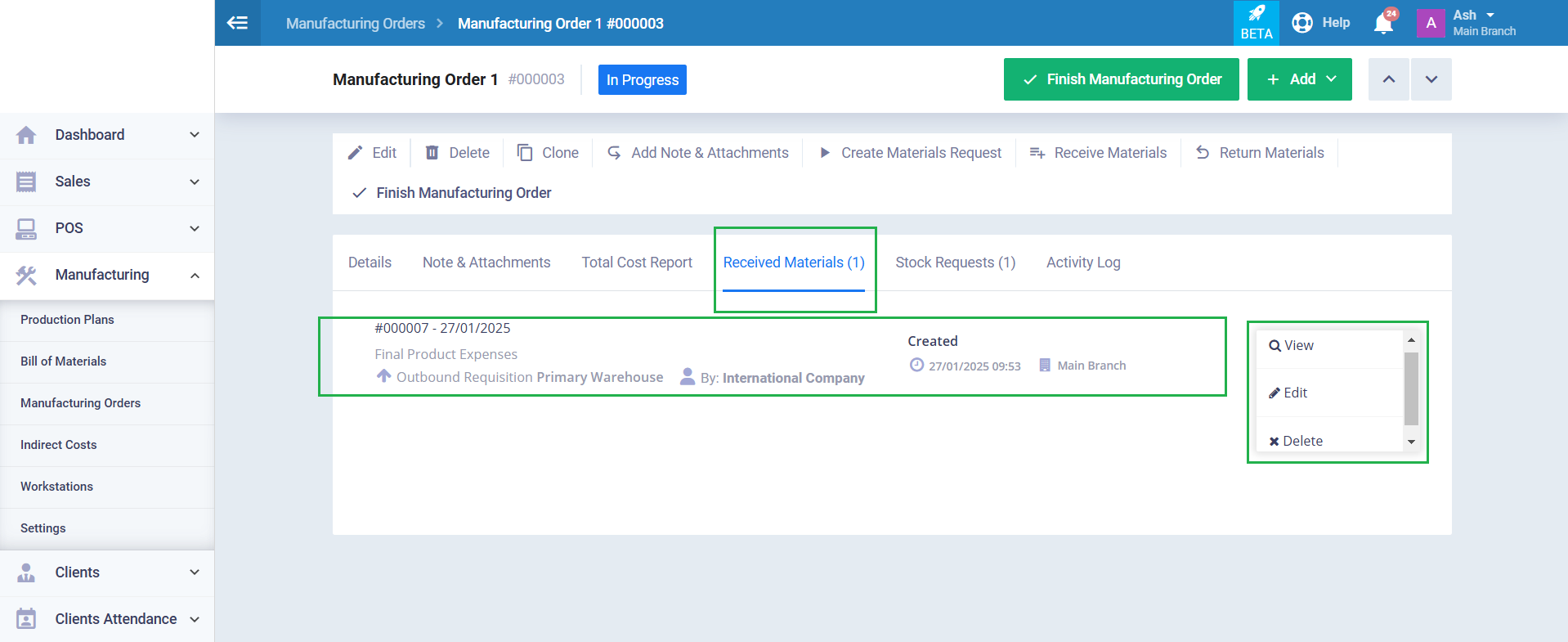

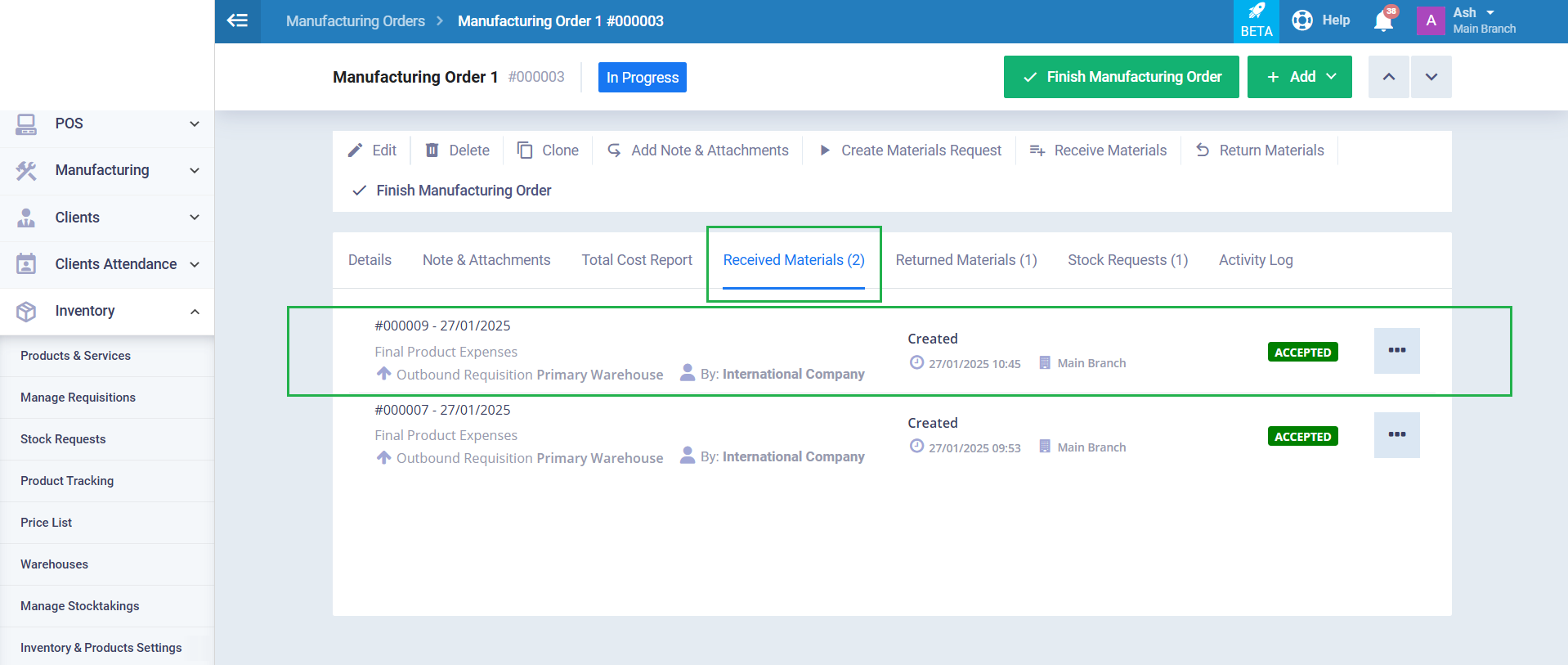

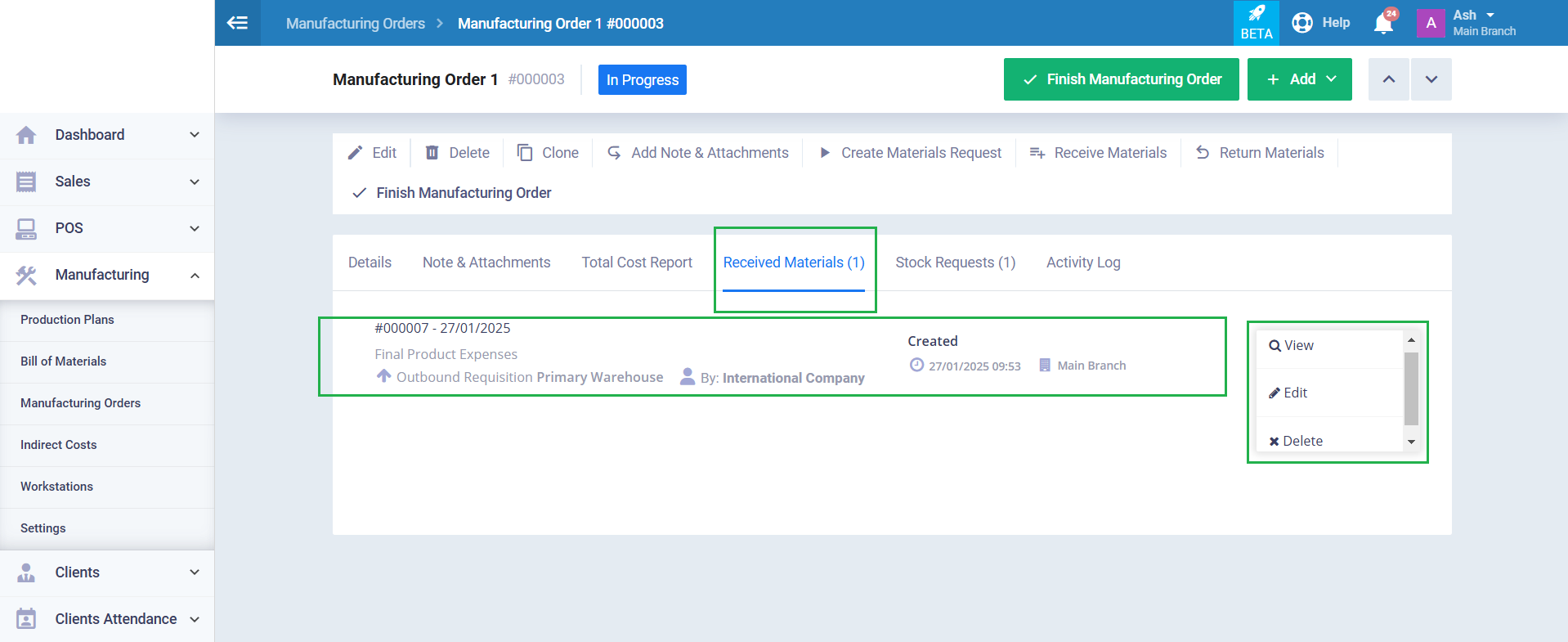

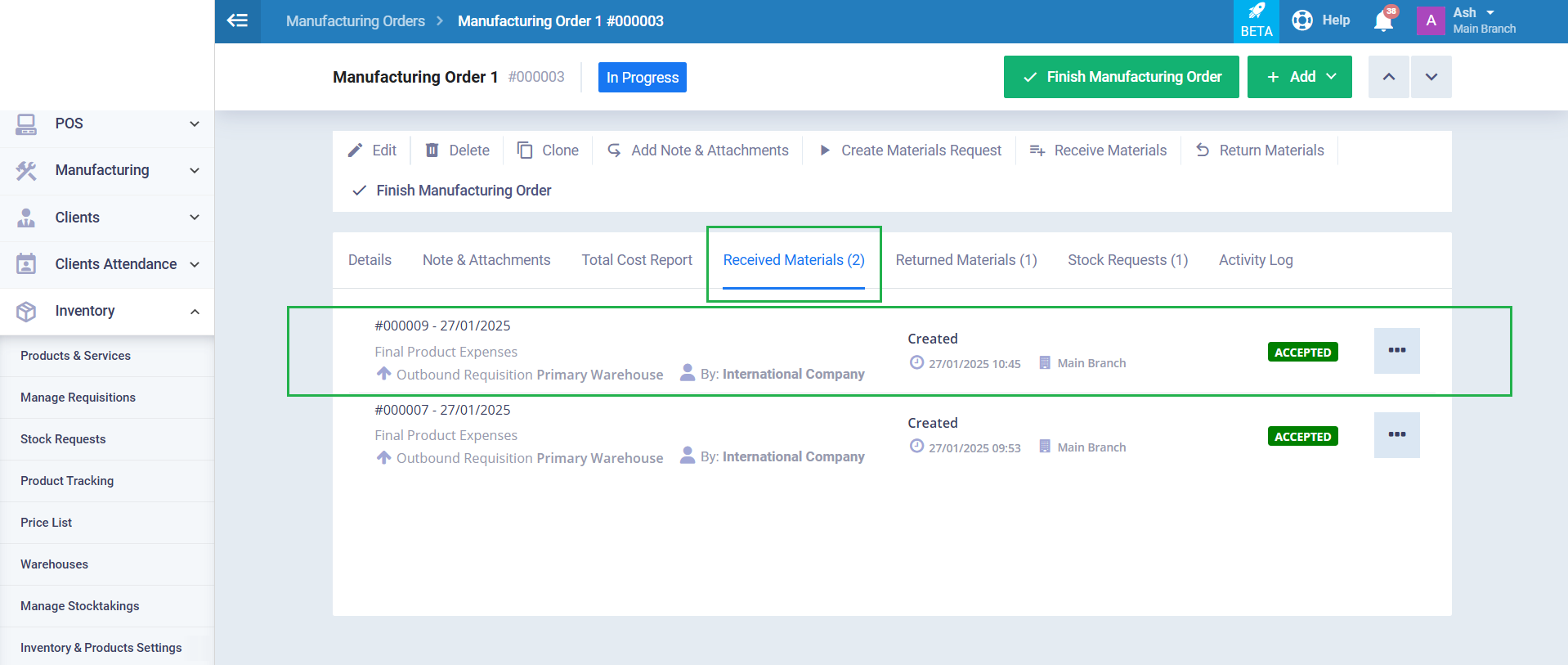

You can find the raw material requisition associated with the manufacturing order under the “Received Materials” tab in the screen of the desired manufacturing order. Using the three dots next to the requisition, you can view, edit, or delete the requisition.

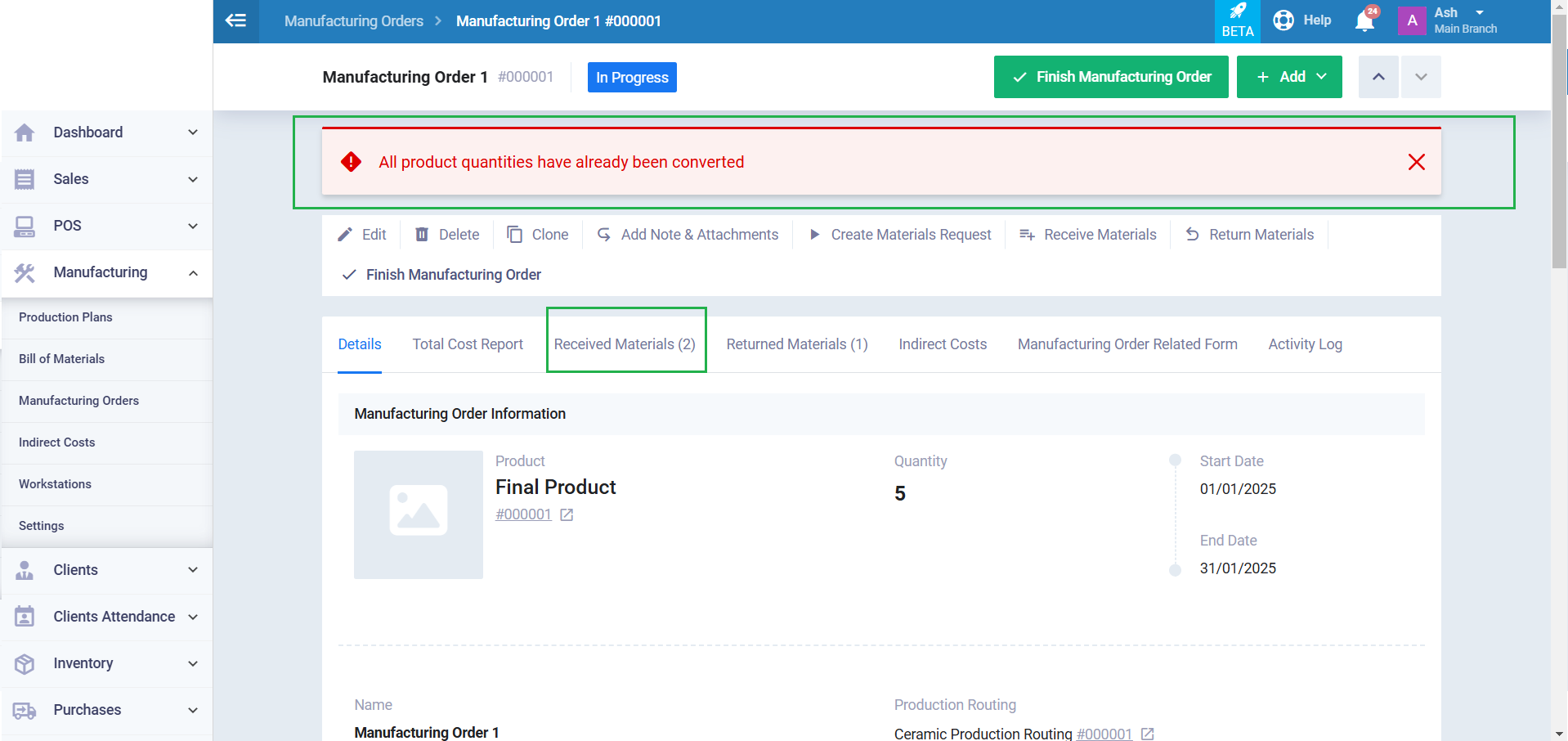

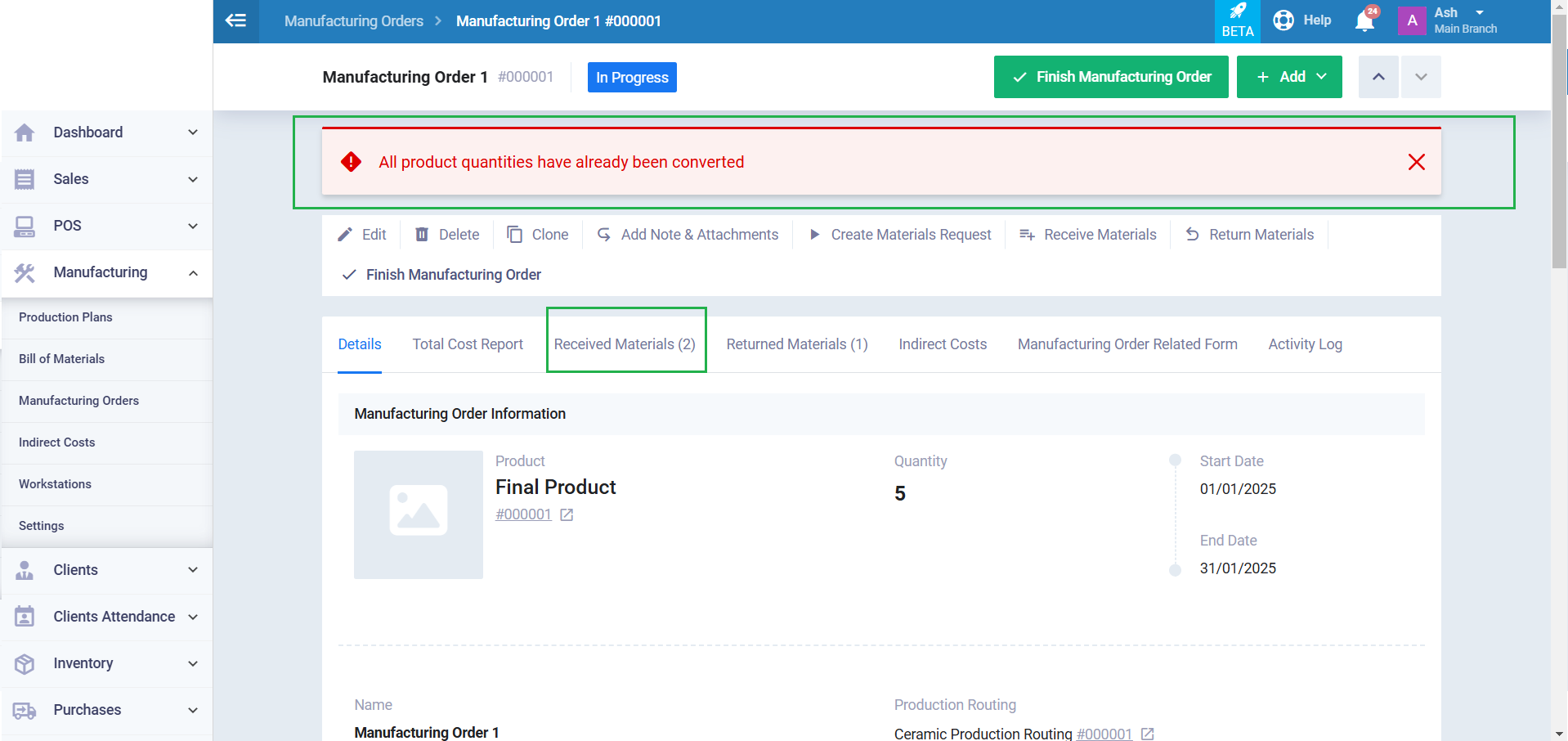

If you have received all the raw materials specified in the manufacturing order, you will not be able to receive these raw materials again. When you click on “receive materials,” the following error message will appear:

“All product quantities have already been converted.”

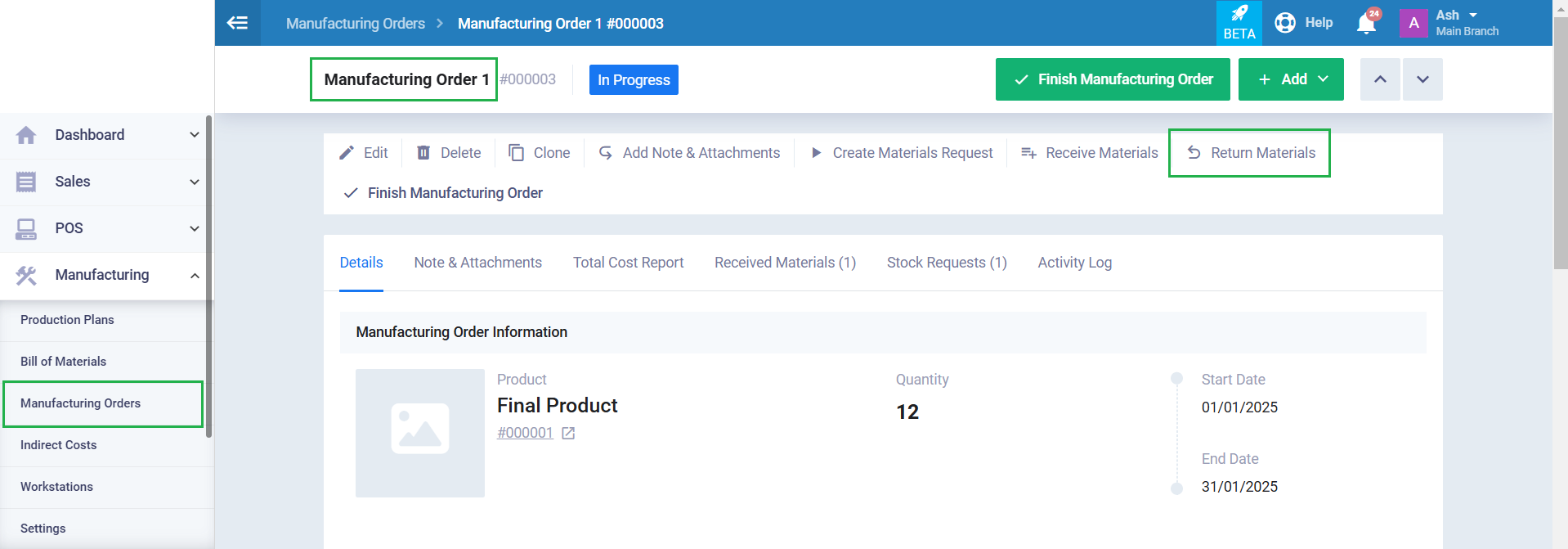

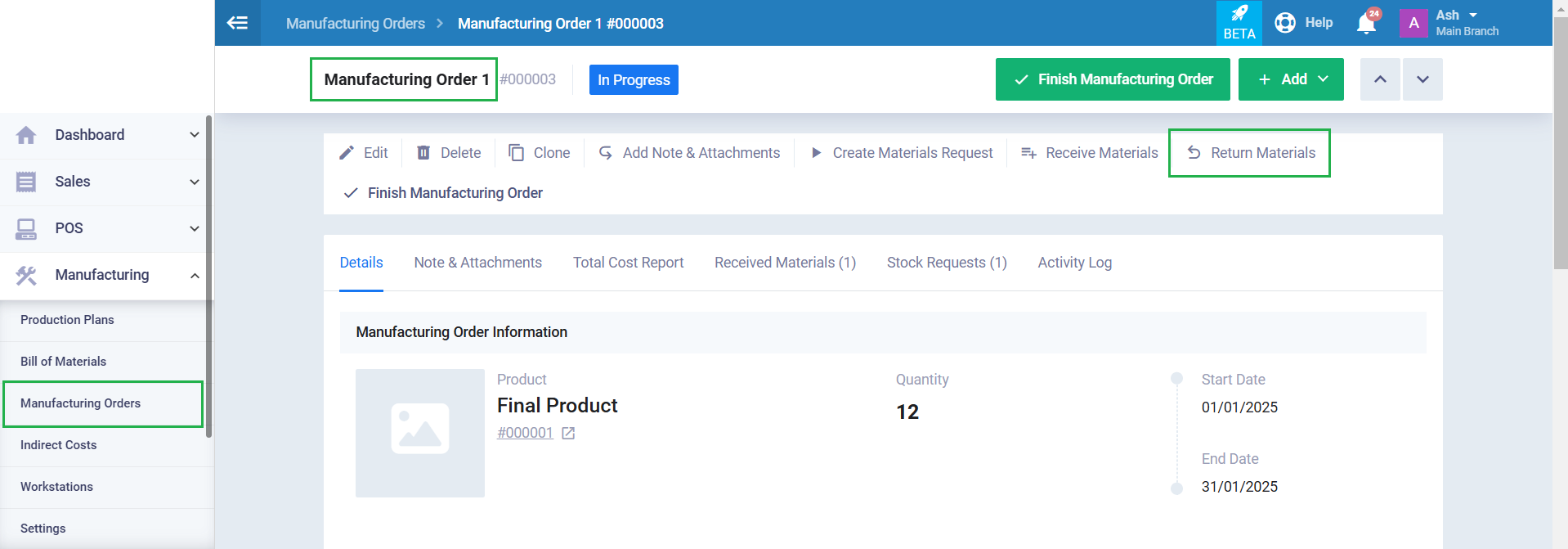

You can return all or part of the manufacturing order received materials, provided that the raw materials have already been received.

To return materials, click on “Manufacturing Orders” under the “Manufacturing” dropdown in the main menu, select the desired Manufacturing Order, and then click on “Return Materials.”

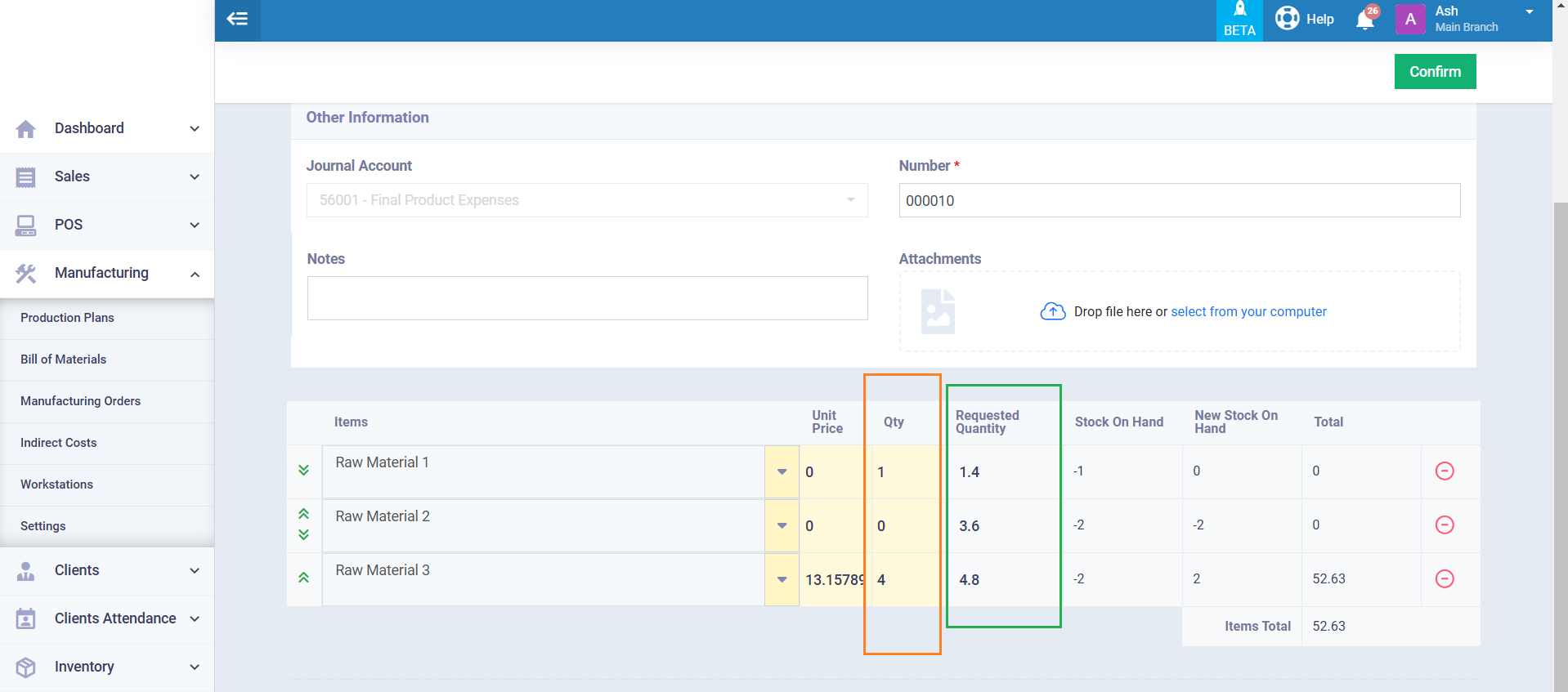

The same raw materials specified in the Manufacturing Order, along with their quantities, will automatically appear in the return materials requisition. You can choose to return all the raw materials or adjust the type and quantity of the materials you wish to return.

When a return is created, the inventory increases by the same quantity being returned, as the return of materials is considered an inbound stock requisition.

After finalizing all the details, click on the “Confirm” button to complete the process.

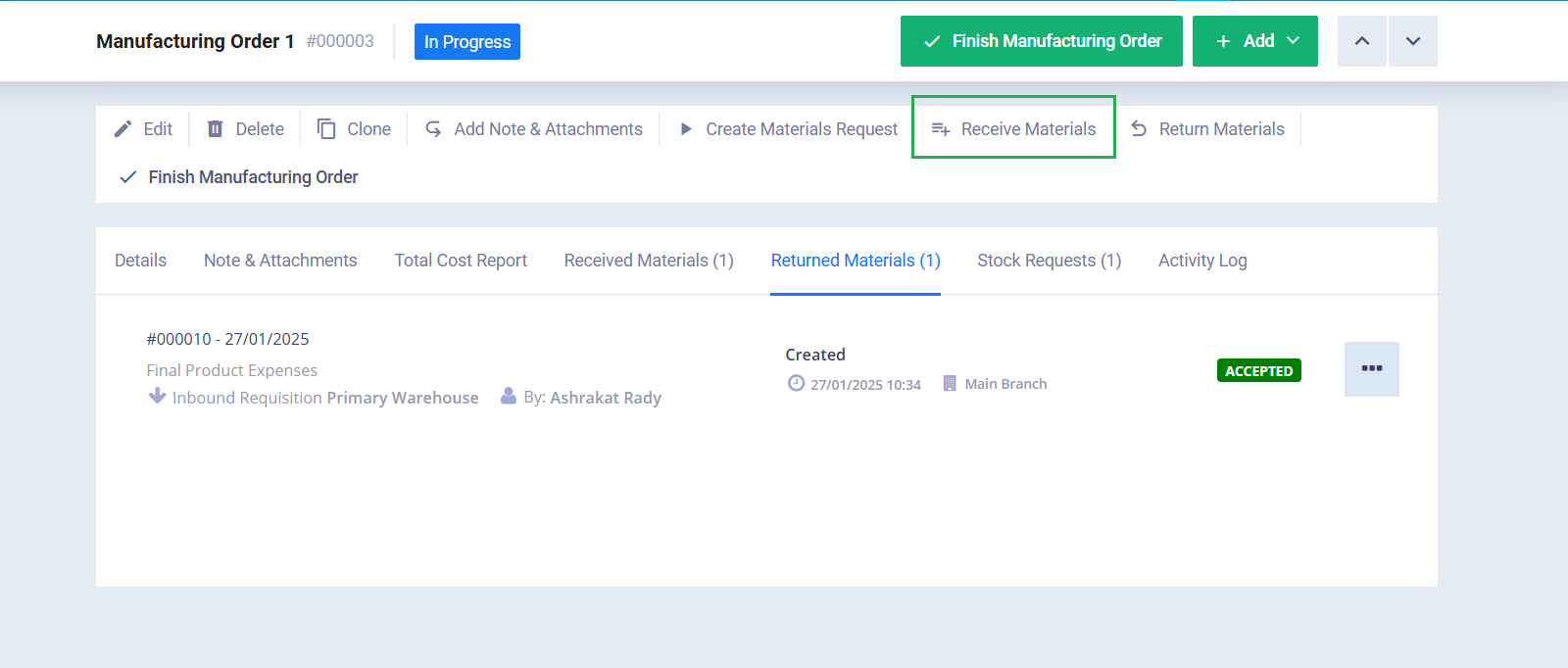

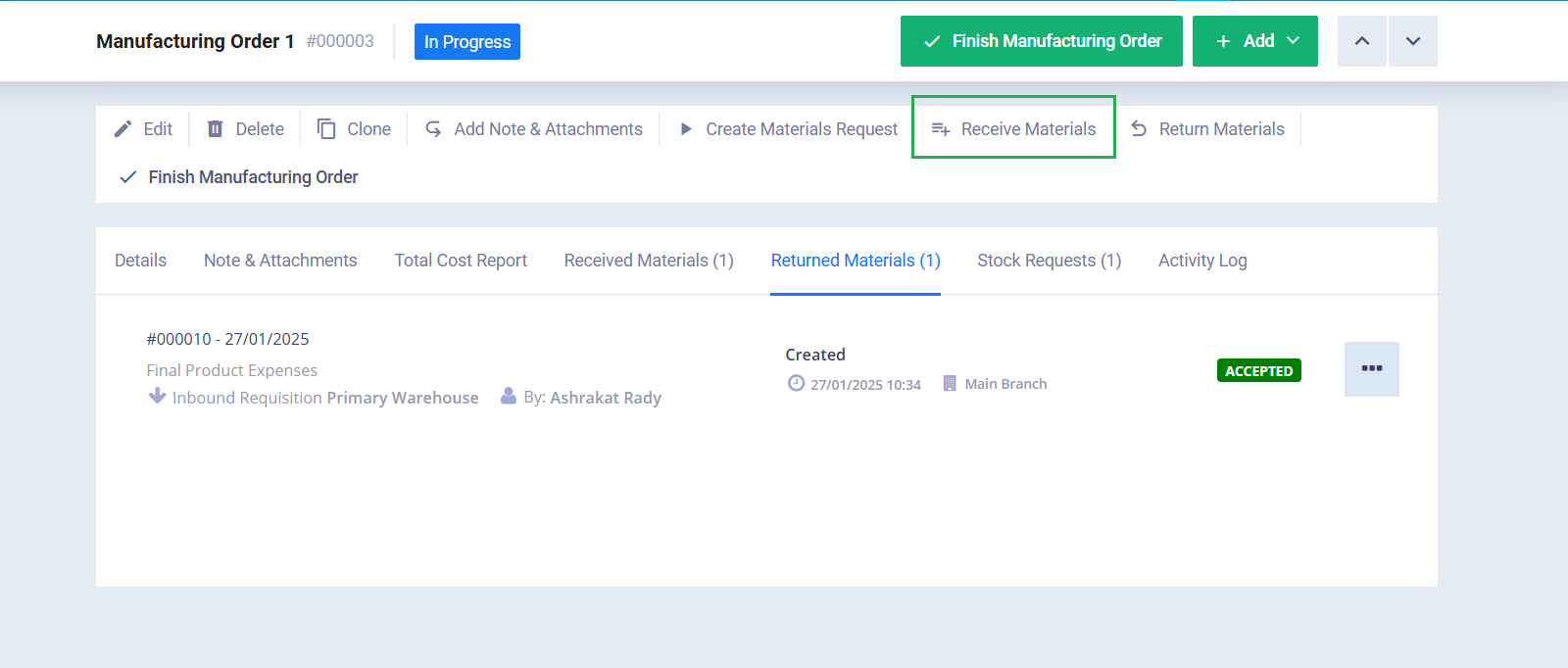

After confirming the return requisition, it will appear within the associated manufacturing order under the “Returned Material” tab. By clicking on the three dots next to it, you can perform various actions such as View, Edit, or Delete.

If some materials have been returned, you can receive them again by clicking on “Receive Materials.”

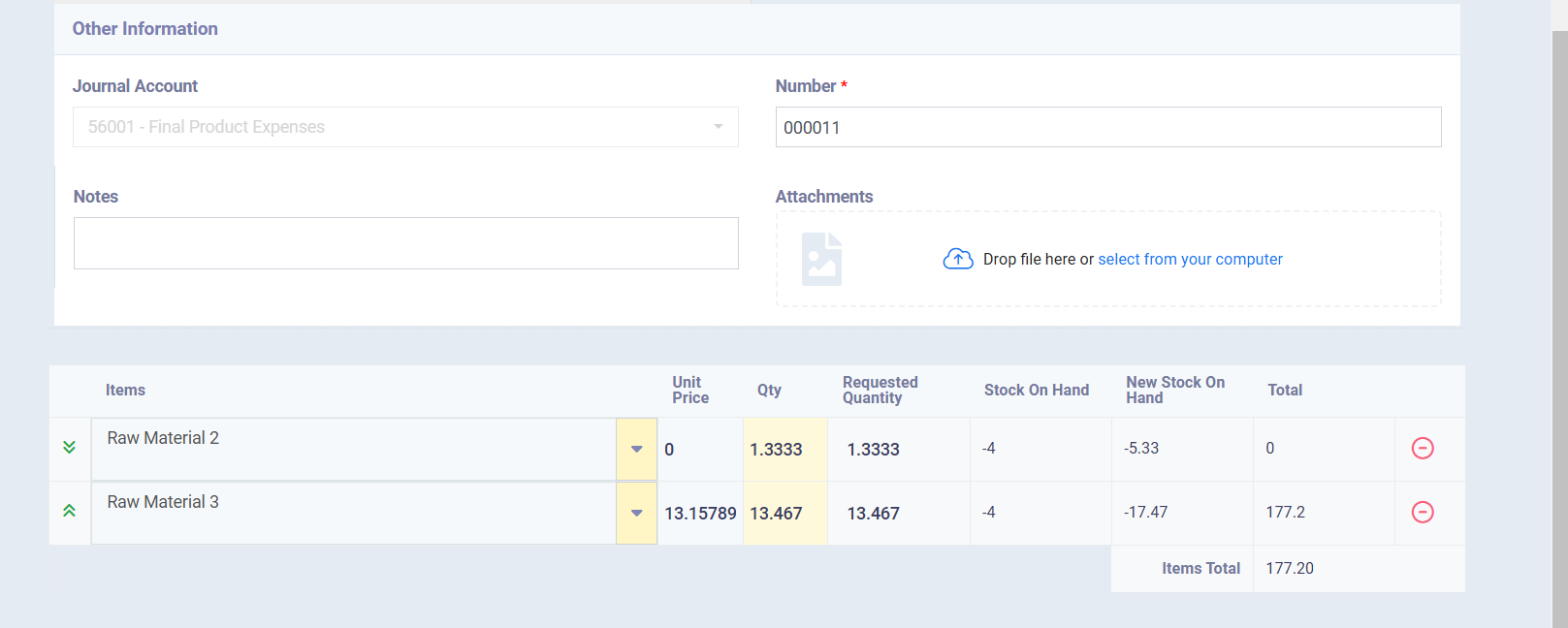

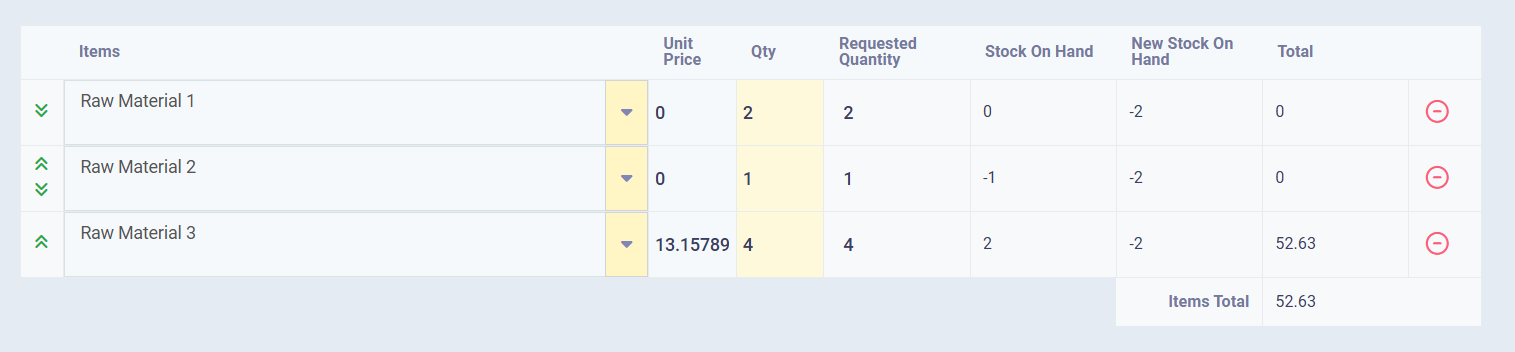

The raw material requisition will display only the materials that were returned or those that were not initially received. Adjust the details as needed and click on the “Confirm” button to finalize the process.

The raw material requisition for the materials that were previously returned will appear under the “Received Materials” tab.

In addition to receiving raw materials from the manufacturing order screen, you can also receive them through the stock requisitions screen. To do so, click on “Manage Requisitions” under the “Inventory” dropdown in the main menu, then click on the “Add” button and select “Manufacturing Materials” from the dropdown menu.

From the dropdown menu, select the manufacturing order for which you want to receive the raw materials, then click the “Submit” button.

You will see the raw material requisition screen. Make any necessary edits and adjustments as previously mentioned in the earlier sections. Once finished, click on the “Confirm” button.