Manufacturing Order Scrap Items

There are various approaches to managing scrap items resulting from manufacturing orders, depending on the industry, the nature of the scrap, and each company’s policies. With Enerpize, you can customize the system to handle scrap items and process them per your accounting requirements. This guide outlines the basics of how the system manages scrap items.

Adding Scrap to Inventory and Selecting in Manufacturing Order

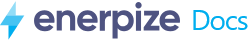

To add a new scrap to your inventory, click “Products & Services” under “Inventory” in the main menu. Then, click the “Add” button and select “New Product” from the dropdown menu.

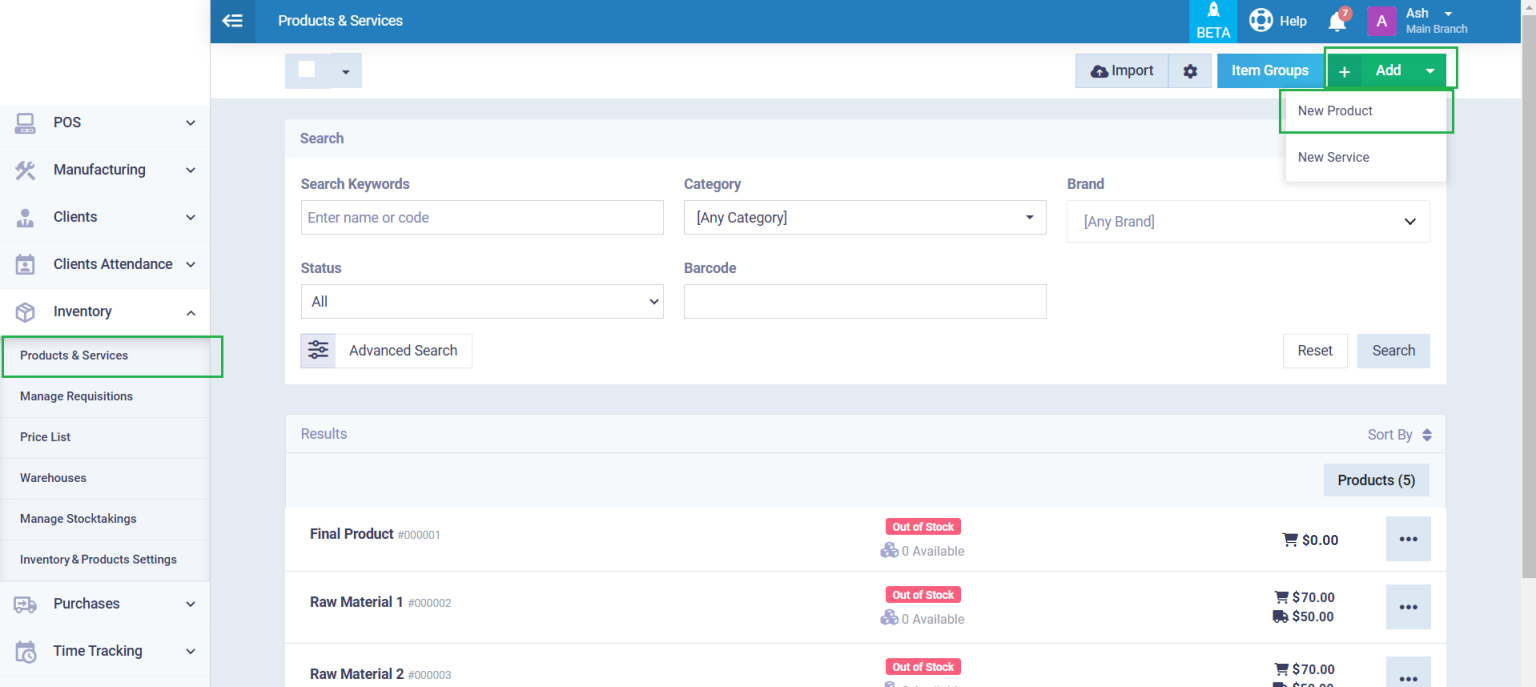

Enter the name of the scrap item and its selling price if it is resalable. Complete the scrap product details and click the “Save” button.

If you add scrap materials within the Bill of Materials (BOM), the scrap items will automatically appear in the manufacturing order file associated with this BOM. Their quantity will be adjusted to match the final product quantity specified in the manufacturing order.

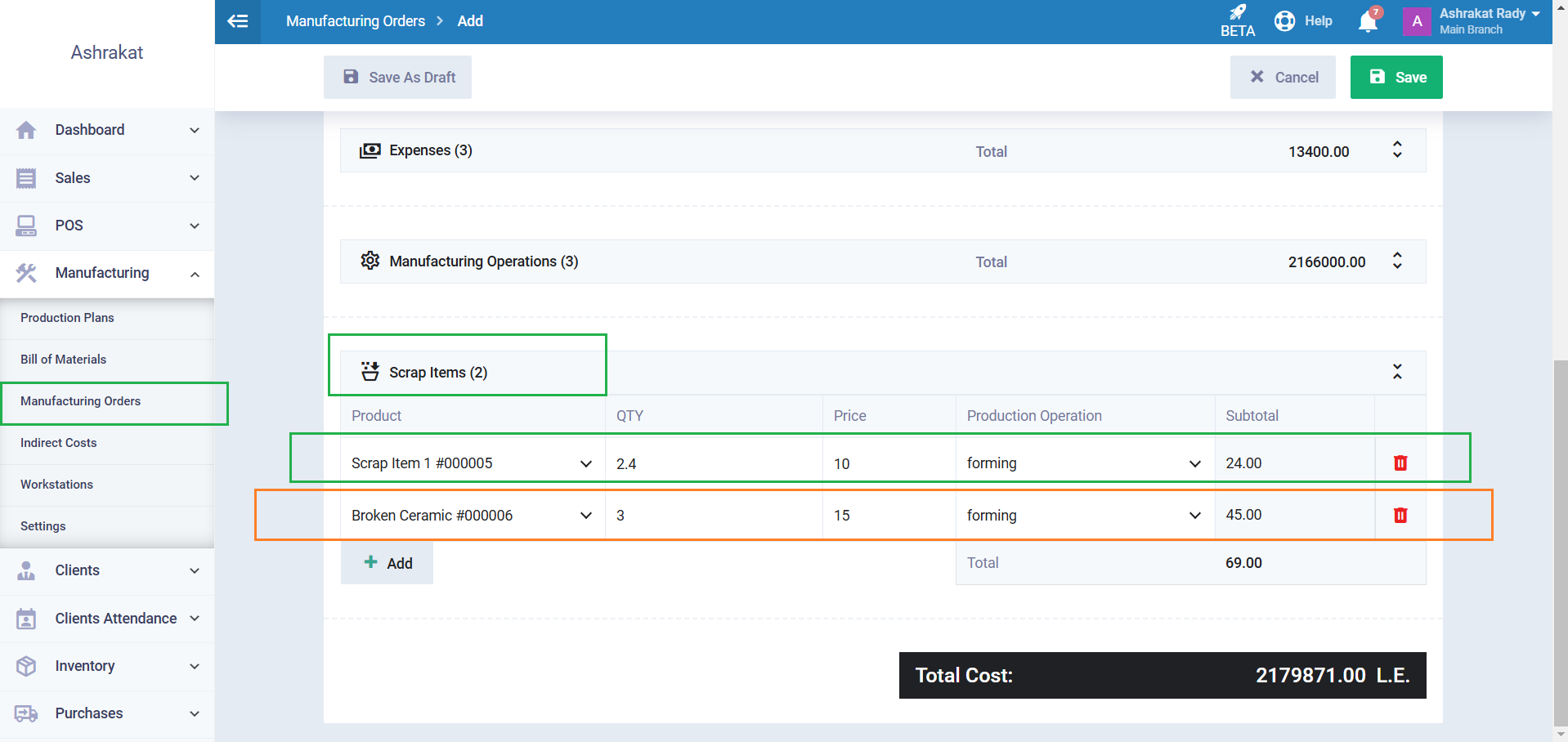

However, if you wish to add scrap materials directly from the manufacturing order, navigate to “Manufacturing Orders” under “Manufacturing” in the main menu, select the desired manufacturing order, and go to the Scrap Items section. Add the scrap items generated from this manufacturing order, specify their price, complete the manufacturing order details, and save it.

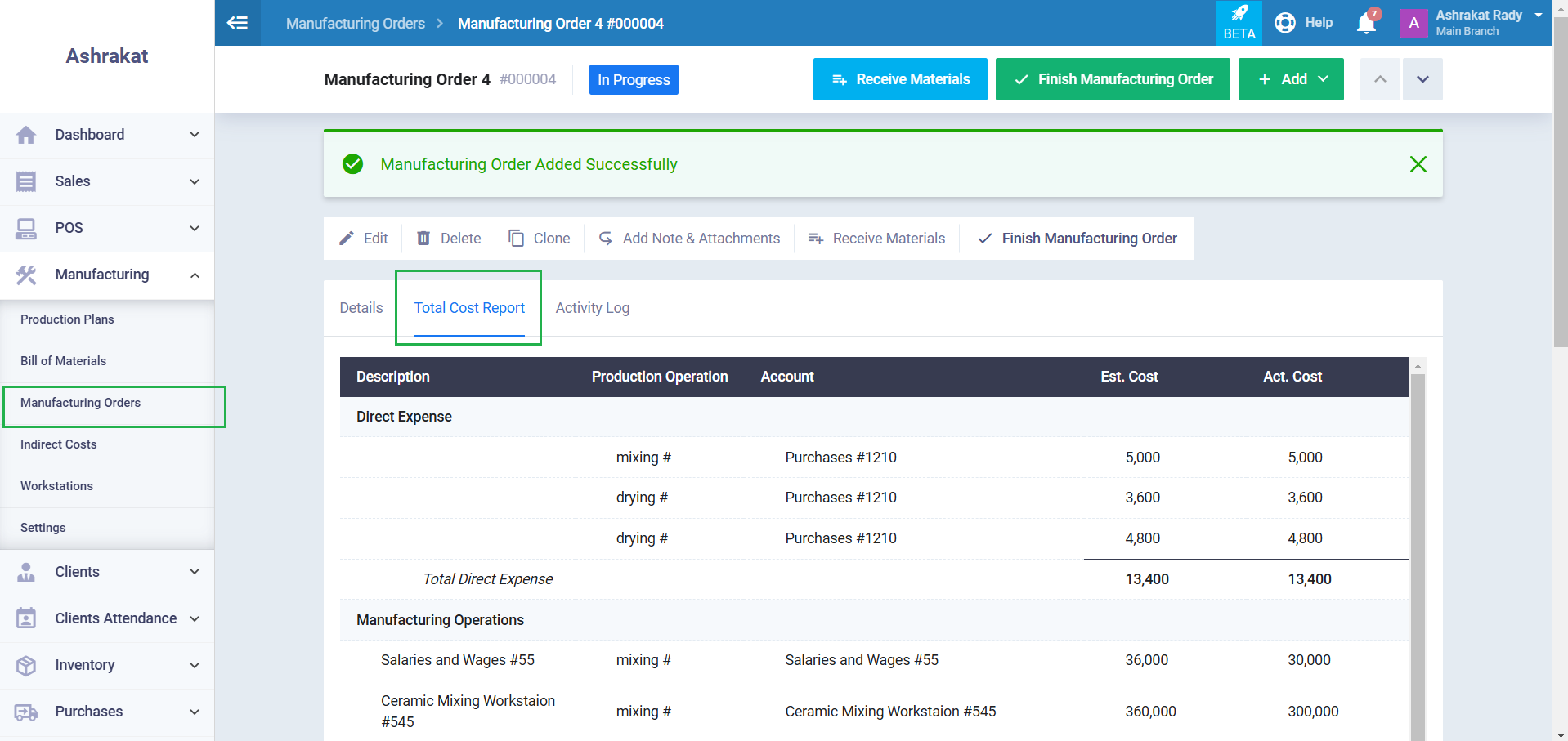

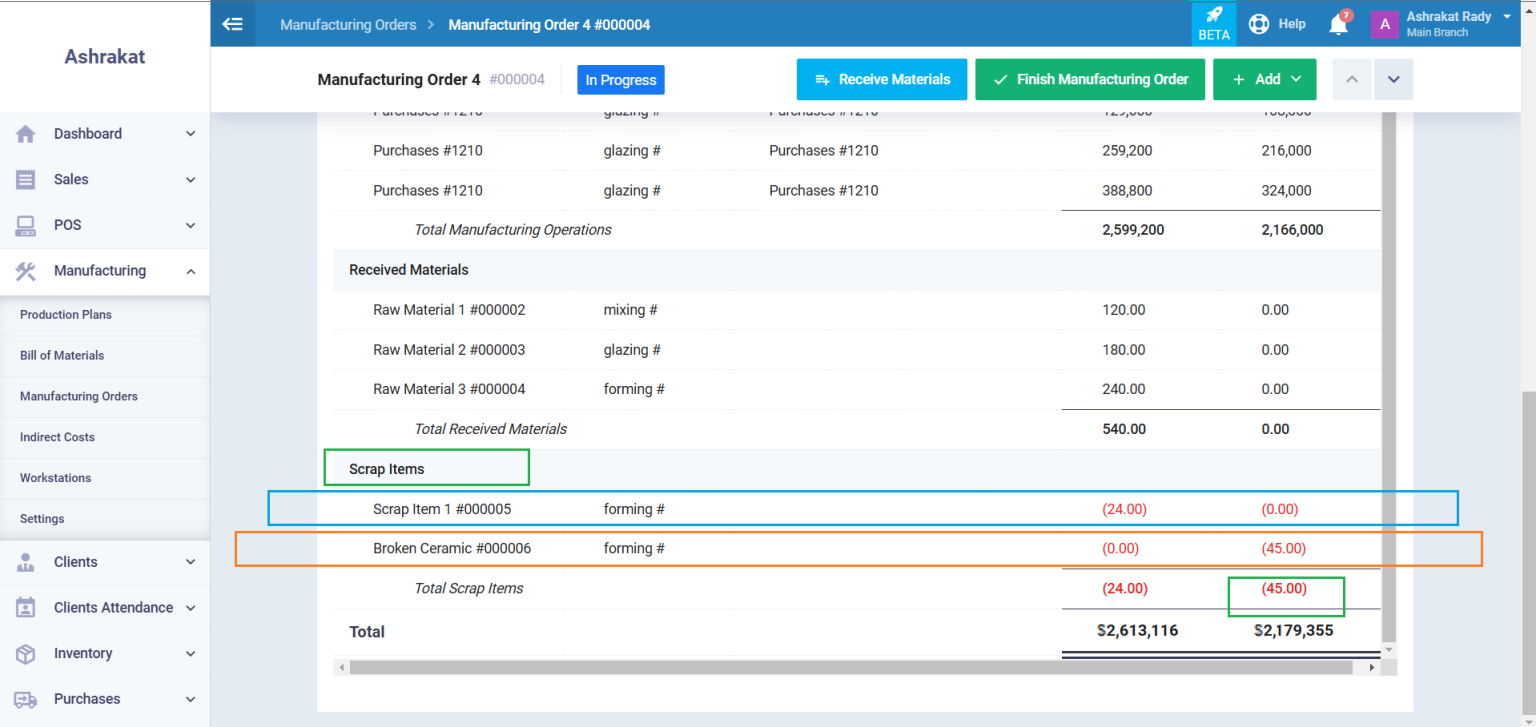

Scrap materials appear as a separate line item in the cost reports.

To view the scrap details in the report, go to the file of the desired manufacturing order and click on the “Total Cost Report” tab.

Navigate to the Scrap Items section in the report to find a breakdown of all scrap items, including their actual cost, expected cost, and the total cost of all scrap.

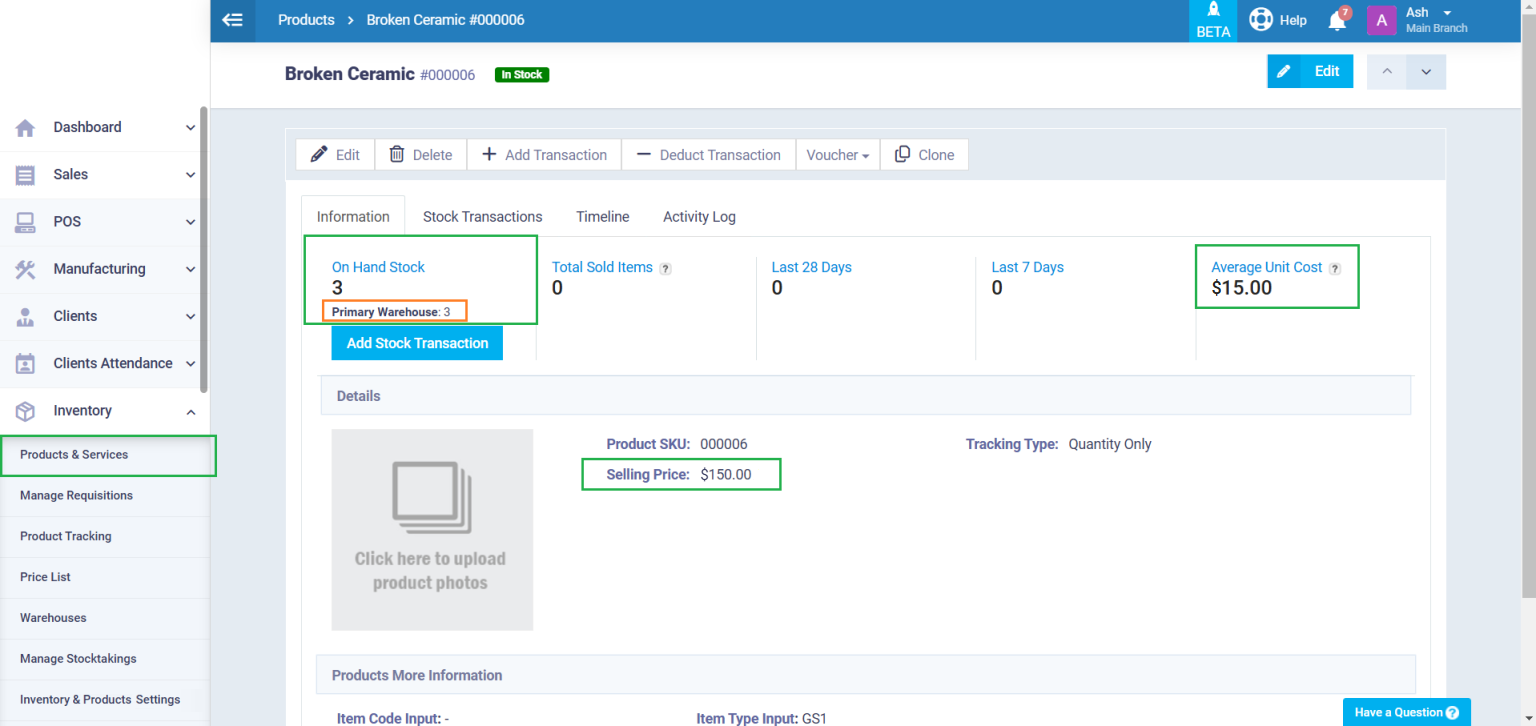

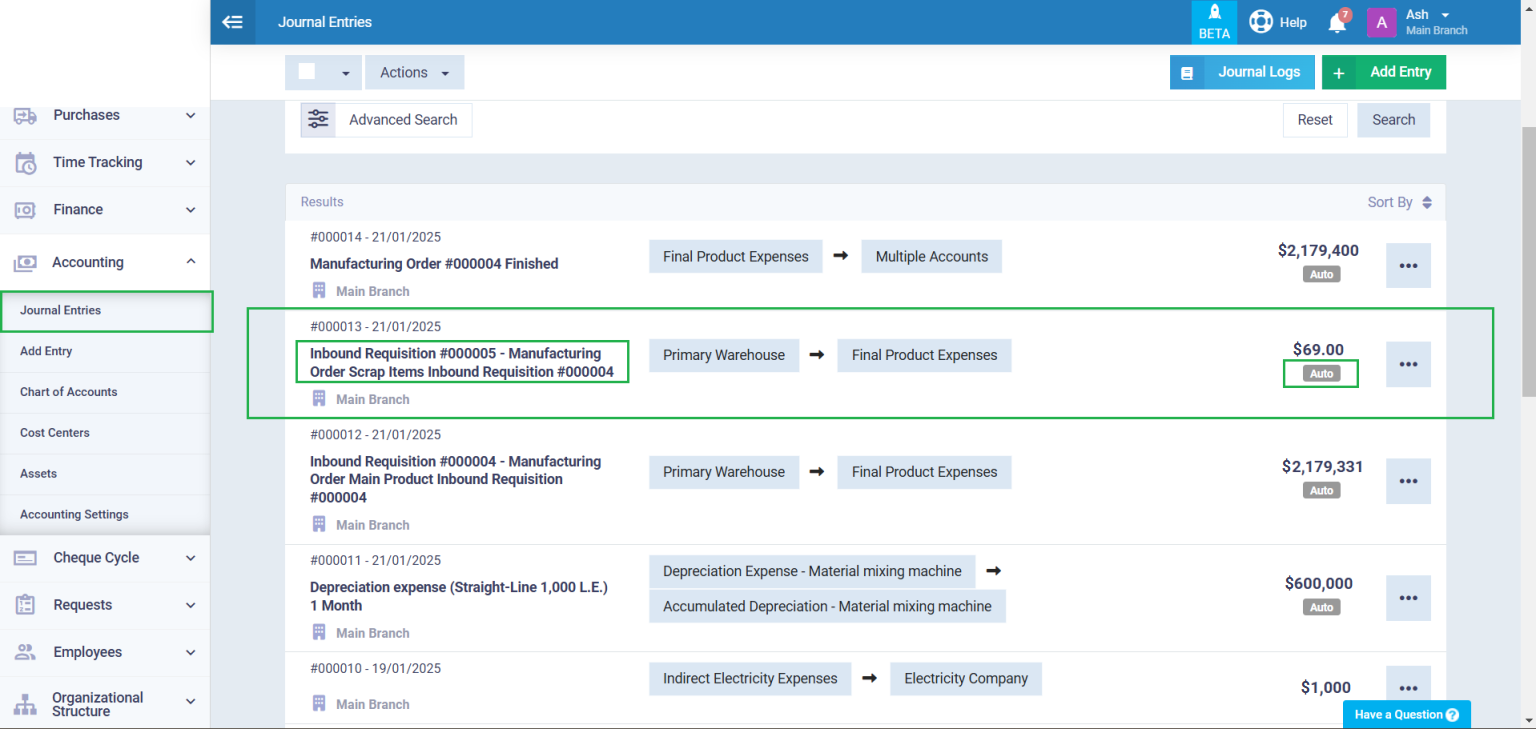

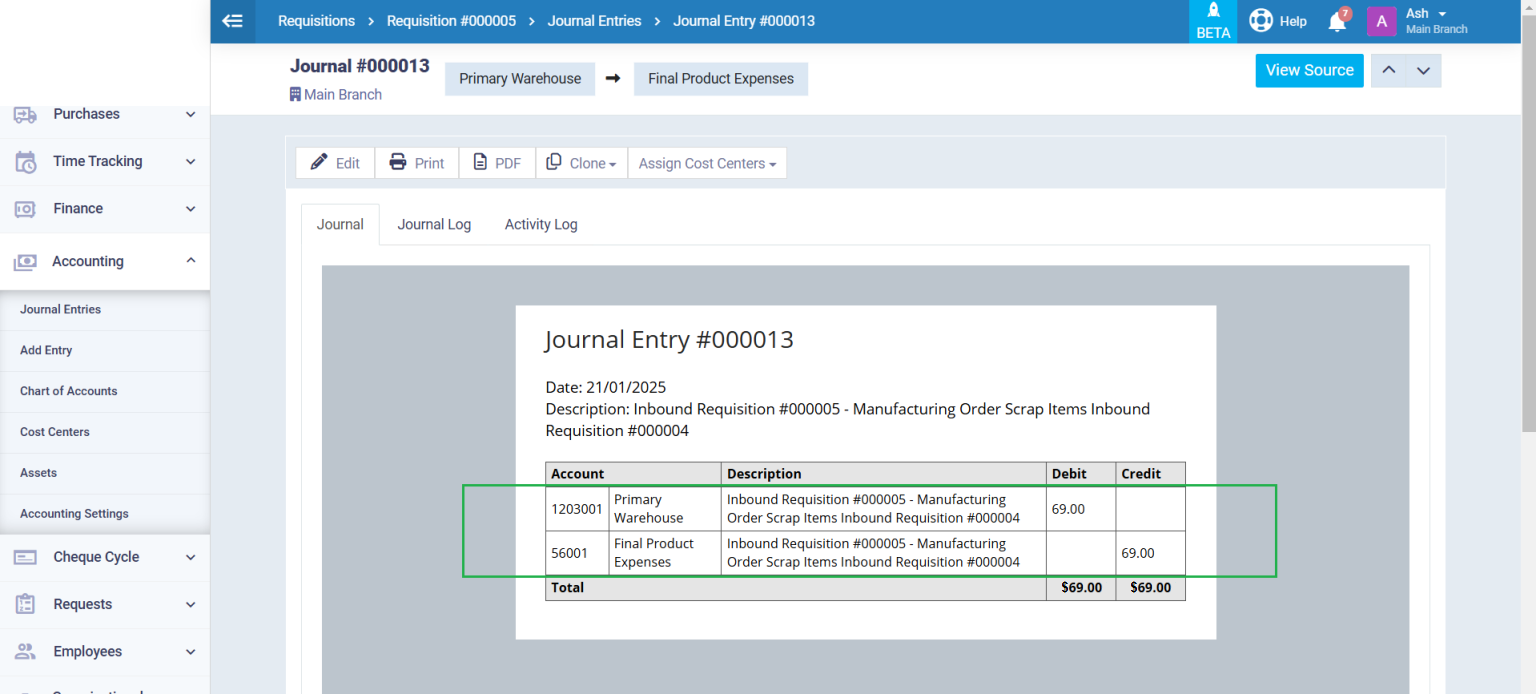

This entry is considered an inbound requisition, which reflected on stock transactions. So the quantity of the scrap item increases in the associated warehouse upon finishing the manufacturing order.