Production Routings Guide

The manufacturing process related to each product typically occurs in several stages. In the system’s provided manufacturing cycle, each part of the manufacturing process is linked to its corresponding stage. For example, if you have a “Production Routing” for ceramic manufacturing, you would then divide the Production Routing into Sub Production Routings each of them called a ” Production Operation” such as: raw material testing, component mixing, molding, drying, glazing, forming, sorting, and packaging.

When creating a Bill of Materials (BOM) or a manufacturing order, you link each raw material, expense, or workstation (manufacturing process) to its corresponding production operation. This ensures that manufacturing reports are categorized so that all manufacturing transactions are linked to the production operation in which they occurred.

Adding a Production Routing

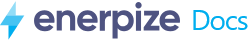

Click on “Settings” from the dropdown under “Manufacturing” in the main menu, then click on the “Production Routings.” card.

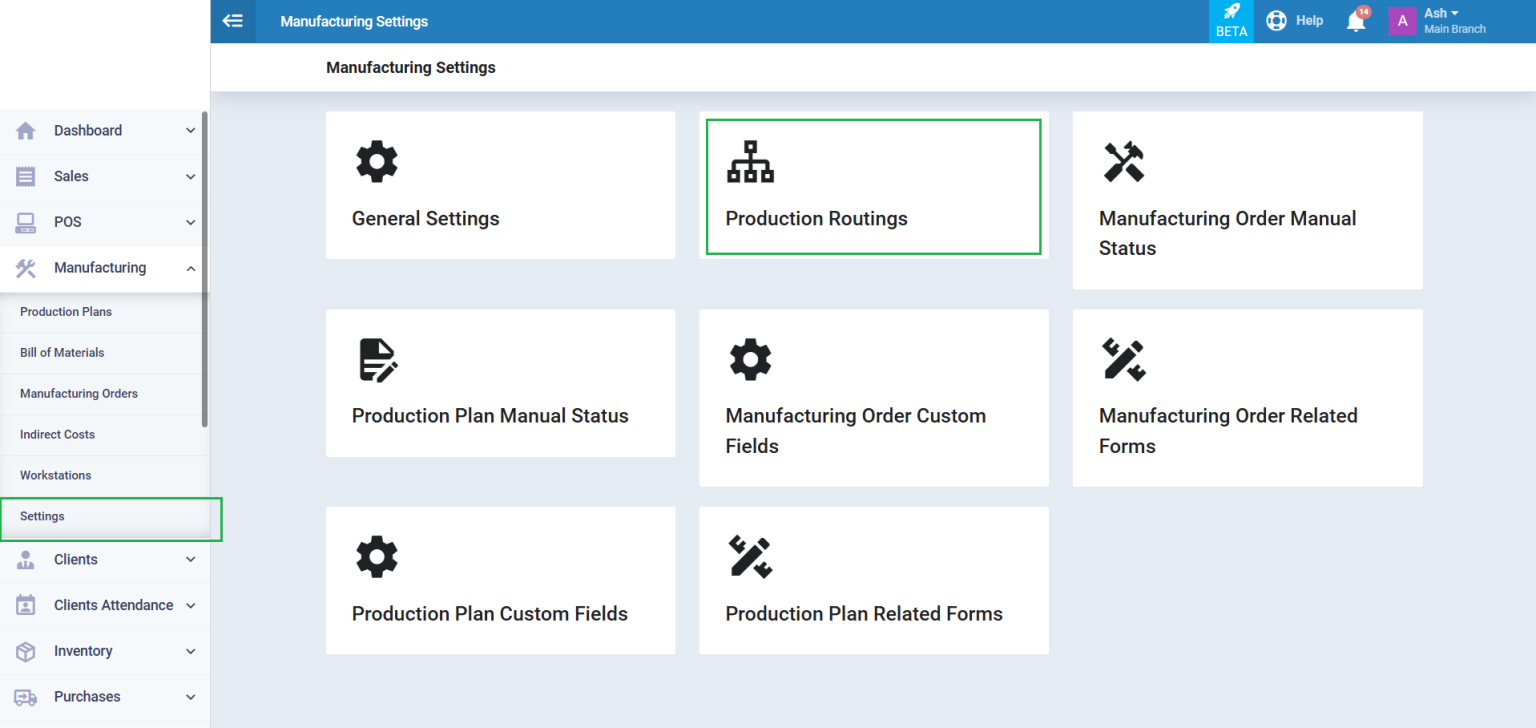

Click on the “Add Production Routing” button.

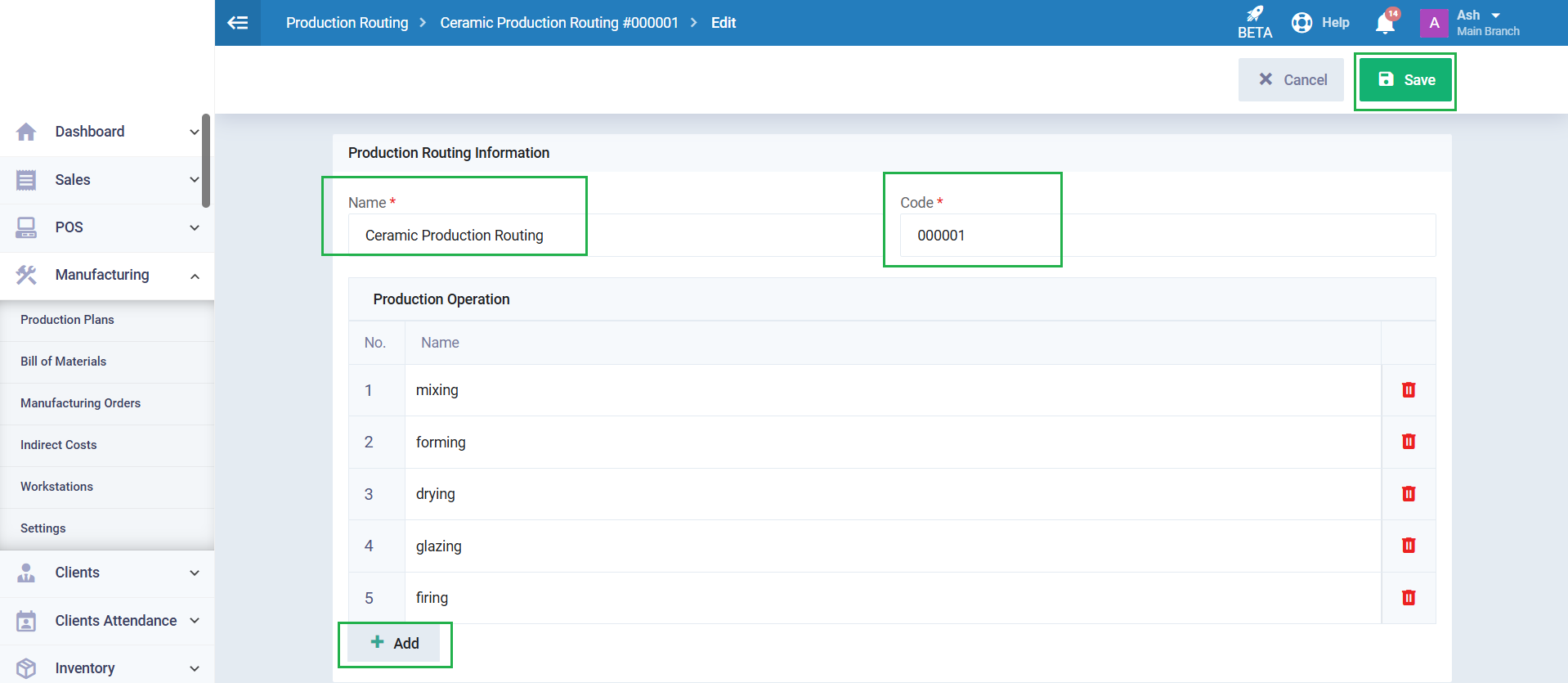

Enter the production routing information:

- Name: Enter a name for the production routing, for example: Ceramic Production Routing.

- Code: This is a unique automatic number generated by the system for each production routing.

Production Operation:

- Name: Enter a name for each production operation included in the routing, such as: mixing – forming – drying – glazing – firing ensuring the stage name matches its order in the production routing.

To add a new production operation within the routing, click the “+Add” button and enter the desired stage name.

Then, click the “Save” button.

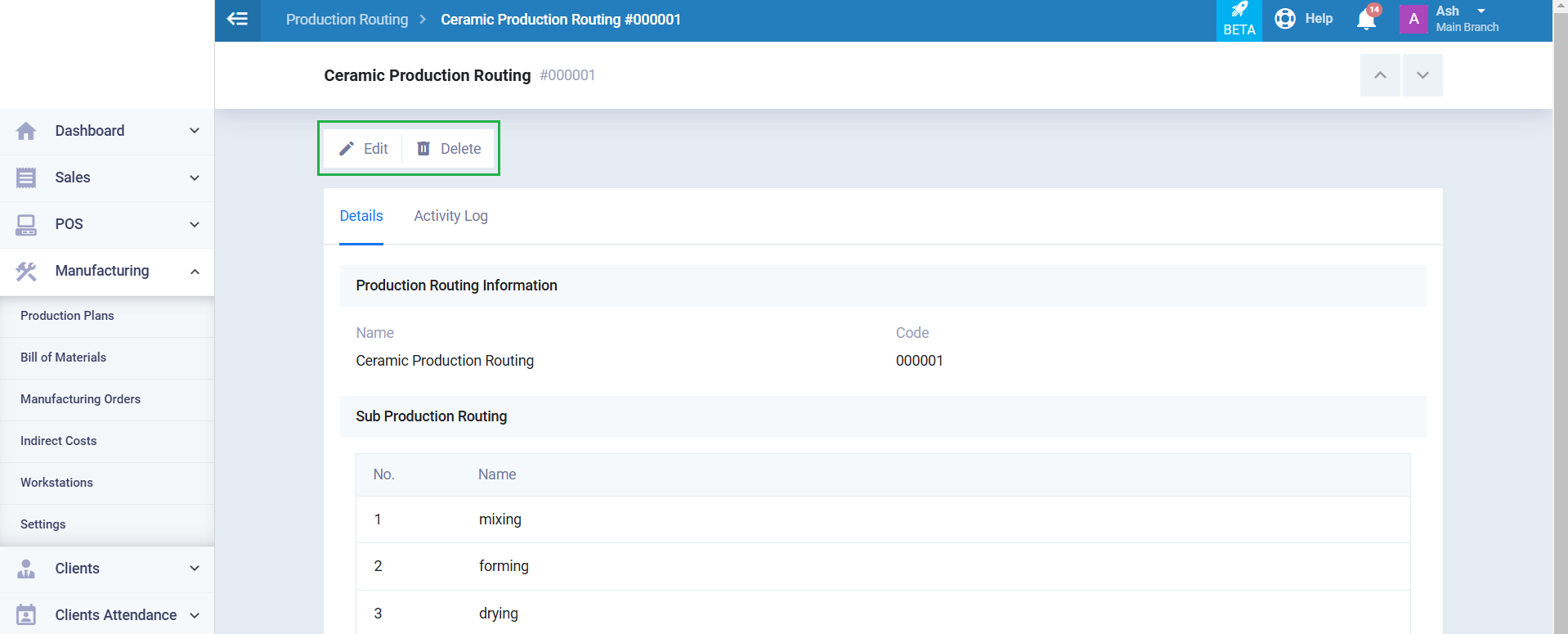

You can perform some actions on the production routing after saving, such as editing and deleting. The Production Routing “Details” tab and the “Activity Log” tab will also be displayed.

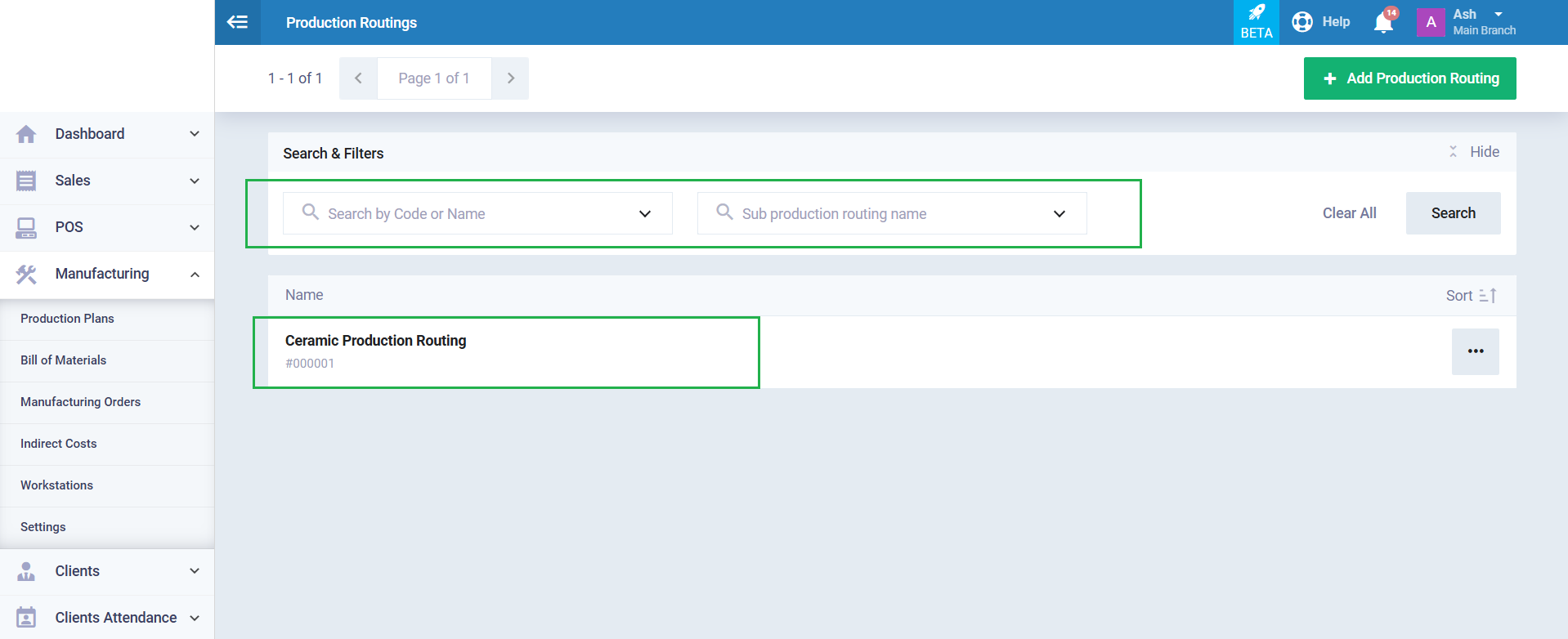

To view the list of production routings added in the system, click on “Settings” from the dropdown under “Manufacturing” in the main menu, then click on “Production Routings.” card.

You can click on the desired production routing to view its details. Additionally, you can use the Search & Filters tools to quickly find the production routing you are looking for.

If you’re wondering about the difference between production routings and workstations, refer to .

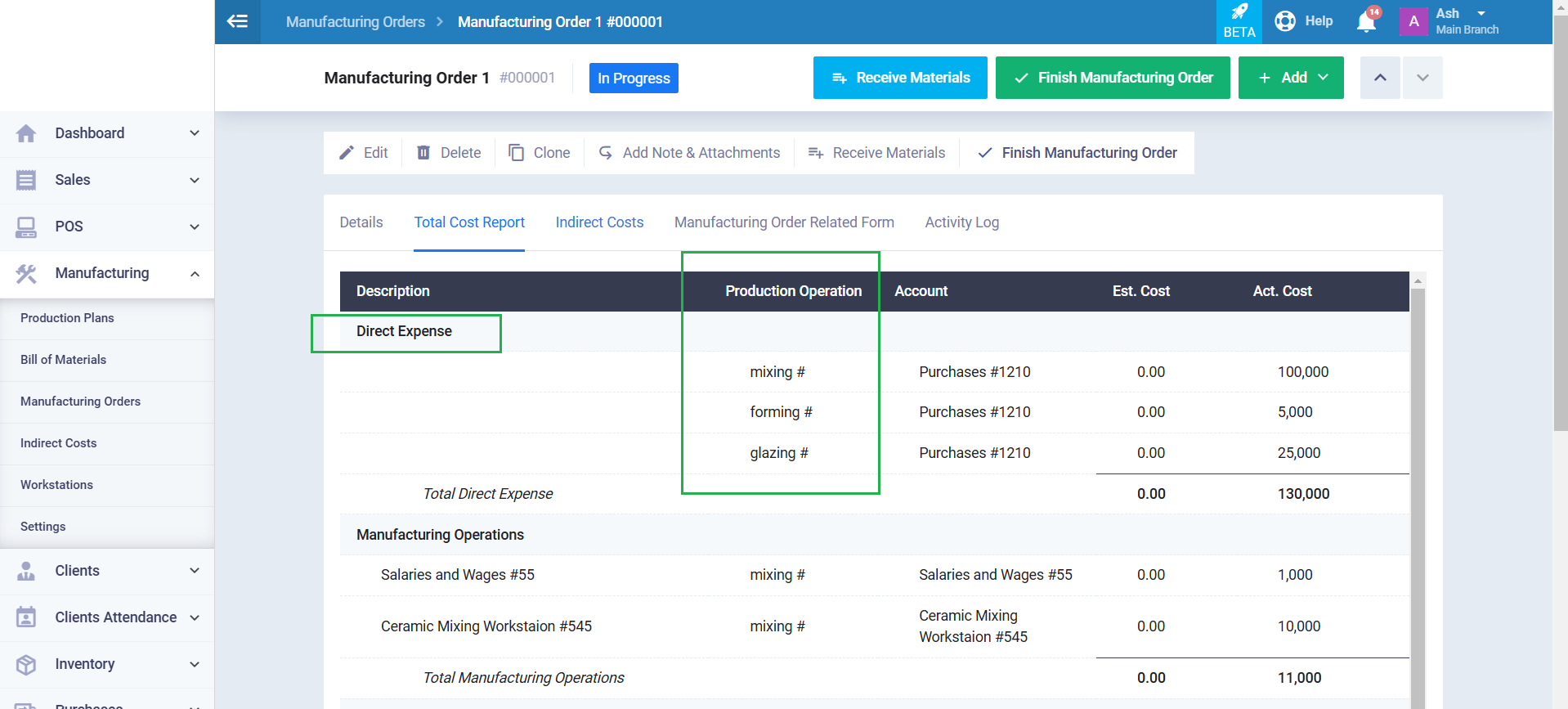

How production operations appear in the total cost report?

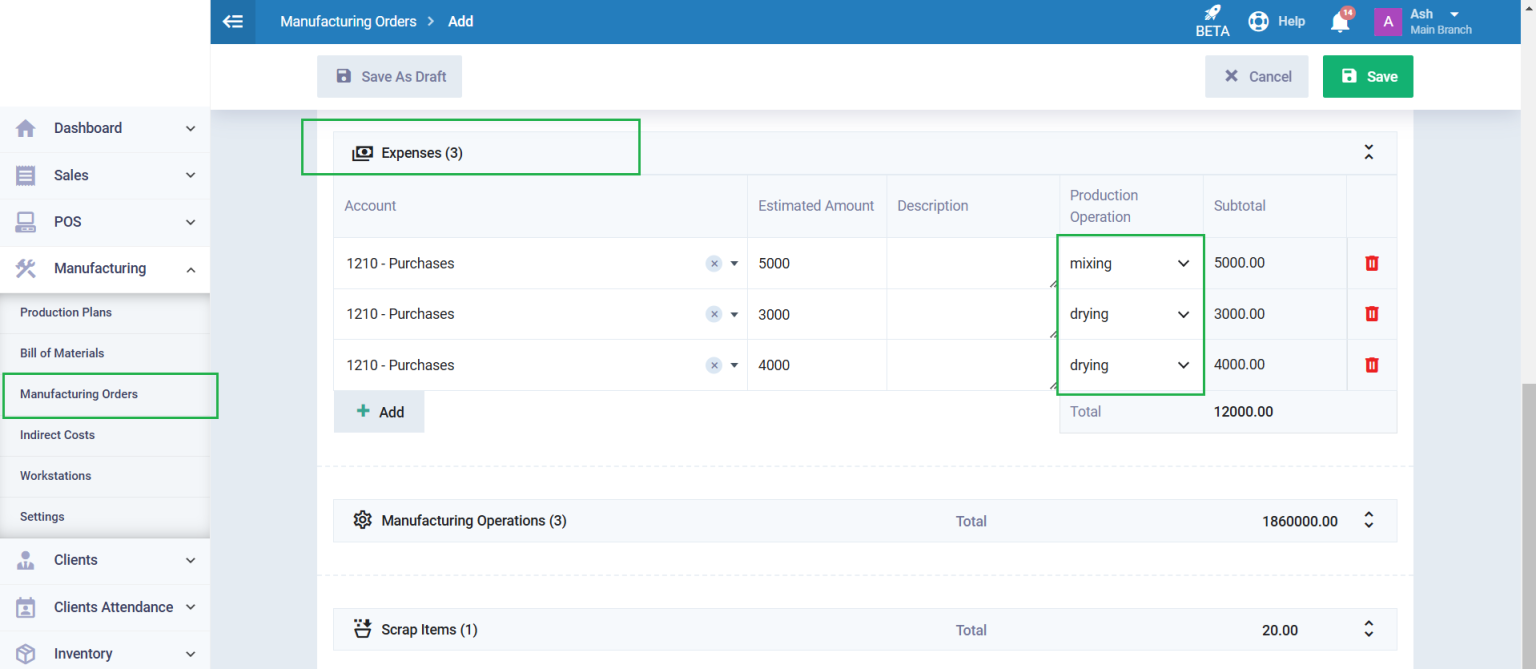

When adding a Bill of Materials (BOM) or a Manufacturing Order, and if a production routing is selected for the BOM or the manufacturing order, the production operation included in that routing will appear next to each item. You can then select the operation in which each manufacturing activity was performed or where each expense occurred.

Later, you will find the total cost report, with the selected production operation displayed next to each item that has an assigned production operation. This helps you analyze and visualize your costs more accurately.